V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

A woodworking miracle that revolutionizes craftsmanship is the Wood Planer Machine. Converting unruly lumber into smooth, consistent planks ensures accuracy. It enhances talents rather than replacing them by fusing new technology with traditional artistic expression. This device boosts productivity by quickly refining resources for more practical and superior manufacturing. Thanks to its sophisticated blade systems and automated adjustments, it adjusts to different woodworking needs. Its user-friendly interface guarantees simplicity, while safety features put well-being first. The Wood Planer Machine is created for growth, longevity, and woodworking abilities, so purchasing one is an investment in greatness. This device combines accuracy and innovation, raising woodworking to unrestricted precision and inventiveness. Continue to read!

It is a crucial instrument in carpentry and woodworking industries since it assists in converting huge, irregular, or rough pieces of lumber into precisely measured and smooth boards appropriate for various woodworking projects. Here are some justifications for the worth of a wood planer machine:

Using a wood planer, you may make a board's thickness uniform along its length and width. For example, making identical wooden panels or boards for furniture manufacture depends on this.

Removing wood layers from the surface with the planer's cutting blades leaves the surface with a smoother, more elegant finish. For woodworking tasks to turn out professionally, this is crucial.

Dimensional accuracy is important to ensure that joints fit properly and that projects are put together correctly. Wood planers help you make boards with precise measurements.

A planner can assist you in removing the exterior layers of wood that may be uneven, bent, or contain faults when working with rough lumber. Using more useful wood, not only enhances the beauty of the wood but can also reduce costs.

For their tasks, woodworkers frequently require particular board thicknesses. They can use a planer to alter the board thickness to meet their design specifications.

Planers can be used to flatten and straighten warped or twisted boards, making them easier to work with and improving the joints' quality.

Hand planing, which takes a lot of time and energy, is necessary to achieve uniform thickness and smoothness in wood without a planer. The process is considerably sped up using a planer.

Wood planers are flexible tools for various woodworking projects because they can handle a wide range of wood species, widths, and thicknesses.

The surface of the wood can be prepared using planers for subsequent finishing procedures, including sanding, staining, or applying a protective finish.

When working with ancient or reclaimed wood, a planer can remove layers of grime, paint, or other impurities to reveal the clear, usable wood beneath.

To make sure the tool fulfills your unique requirements and yields the intended results, selecting the best wood planer machine necessitates careful consideration of several criteria. The following are vital factors to think about:

To be sure the planer can handle the size of wood you often work with, consider the maximum width and thickness it can handle.

Larger, harder woods are typically handled more effectively by a motor with more power. To prevent stress on the machine and produce smooth cutting, look for a motor with appropriate horsepower.

You may obtain various levels of material removal and surface finish thanks to adjustable cutting depth and feed rate settings.

Because of the spiral configuration of the cutting inserts, helical cutter heads provide smoother cuts and less tear-out.

Typically used and reasonably priced, but may cause more tear-out.

Effective dust collection is crucial to keep your workspace tidy and preserve clear sight while working.

To avoid sniping (removing extra material at the start or end of a board), look for infeed and outfeed tables that support longer boards.

Accurately maintaining consistent thickness and precision in regulating cutting depth is essential to get the desired results.

Workflow is made more accessible by intuitive controls and a simple setup.

To ensure dependability and excellent customer service, look for recognized brands with strong user reviews.

For safer operation, look for features like emergency shut-offs, blade guards, and anti-kickback devices.

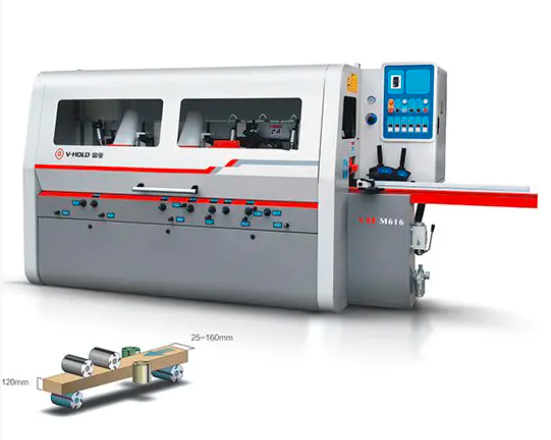

A major, well-known company that integrates woodworking machinery research, processing, marketing, and application service is V-HOLD Woodworking Machinery Make Co., Ltd. V-HOLD, established in 1996, is dedicated to giving its clients worldwide the most dependable, effective, energy-saving, and affordable production equipment. The majority of products available today include a four-sided molder, a double-sided planner, a single-sided saw, a multiple-sided saw, and a multiple-sided saw with a double-sided planner. V-HOLD has figured out how to produce things very efficiently. In addition, V-HOLD has a strong foundation thanks to its collaboration with a renowned management consulting firm and the adoption of cutting-edge business administration tools like ERP and 6S.

Under the guidance of professionals, the V-HOLD Machinery created various items. We aspire to assist you as effectively as we can. We chose our top three Wood Planer Machines to review to facilitate your decision-making. Here is the evaluation of them:

● The 4-Side Moulder and Multiple Rip Saw are combined in the M621HS, making it more than one machine.

● It can speed up wood processing and increase effectiveness. Professional answer for processing shuttered windows, wall hanging wood, sauna board, and other multi-piece mold.

● Containing a shaft cooling and cleaning system purpose, it can raise the saw's lift blades and guarantee cutting accuracy.

● After machining, four groups of action wheels ensure smooth material out-feeding.

● The pneumatic pressure wheel can adjust the material feeding individually to provide smooth feeding of varying thicknesses

● The operator was guaranteed against damage by returned wood chips thanks to the anti-return technology.

● In this planer, the setup for the centralized lubrication system makes it easier to lubricate the lifting mechanism.

● Digital display, simple operation, energy savings, and less wear on the mechanical gearbox.

● You may easily adjust the thickness of wood by simply setting the preset thickness at the microswitch.

● The display gate magnetic sensors have substantially higher precision and a thicker body than traditional proximity sensors.

● Only feeds should cease and start during machine emergencies or aberrant reactions.

● The feeding mechanism has a clutch for safe operation and overload prevention.

● This planer has a pressing wheel mechanism for short materials, ensuring the smooth conveying of the short materials.

● Despite the wide range in wood thickness, the front and back press plates can be adjusted separately so that workpieces can be securely pressed against the work surface.

● Our intricate manufacture and high-grade machining tools ensure every accessory's quality.

Invest in top-notch wood planer equipment to take your woodworking projects to new levels. Imagine changing rough, unruly lumber into consistent, slick boards that exude expert craftsmanship with ease. The wood planer sets the stage for flawless joinery and a sophisticated finish by ensuring uniform thickness and an immaculately smooth surface with precision cutting blades.

Copyright © 2020 V-hold Woodworking Machinery Manufacturing Co., Ltd. | All Rights Reserved Sitemap