V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

In the world of woodworking, precision, and efficiency are paramount. Woodworkers, carpenters, and craftsmen constantly seek innovative tools that can streamline their processes and deliver impeccable results. Among the array of woodworking equipment, the 4 Sided Planer stands out as a true game-changer, symbolizing the ideal fusion of technology and craftsmanship. With its remarkable capabilities, this powerful machine revolutionizes the way the wood is processed, elevating raw timber into a realm of smooth, dimensionally accurate boards. In this article, we will delve into the features, benefits, and working of a 4 Sided Planer, highlighting its indispensable role in modern woodworking and unveiling the magic it brings to the workshop.

What is a 4 Sided Planer?

A four-sided planer, also known as a four-sided molder, is a powerful woodworking machine used to shape and smooth wooden boards. It is specifically designed to process all four sides of a piece of lumber simultaneously, resulting in uniform thickness and smooth surfaces. The machine typically consists of four horizontal cutter heads, each equipped with multiple knives, arranged in a sequence. The lumber is fed into the Planer, and as it passes through, the cutter heads rotate and remove material, achieving the desired dimensions and finish.

How Does a 4 Sided Planer Work?

Here's a general overview of how a four-sided planer works:

· Feeding

The procedure starts with feeding the machine with rough timber, either manually or automatically. It is placed up against a feed roller to help the wood move through the Planer.

· Bottom Cutterhead

The bottom cutter head is the initial cutter head in the Planer. It is made up of several cutting knives stacked in a cylinder. This cutterhead rapidly spins as the wood moves through the machine, scraping away particles from the wood's underside.

· Side Cutterheads

The side cutter heads are the subject of the following step. Two side cutter heads, one on each side of the machine, are commonly present in a four-sided planer. Multiple cutting knives are also present in these cutter heads. The side cutter heads revolve and shape the wood's two vertical surfaces as it continues to advance.

· Top Cutterhead

The wood reaches the top cutter head after passing through the side cutter heads. The top cutter head is made up of cutting knives, like the bottom cutter head. It thins out the top layer of the wood, leaving a smooth, uniform thickness on all four sides.

· Outfeed

The wood enters the Planer's outfeed portion after passing through each cutter head. The outfeed roller helps the final, planned piece of wood exit the machine smoothly.

Best Selling 4 Sided Planer You Should Buy

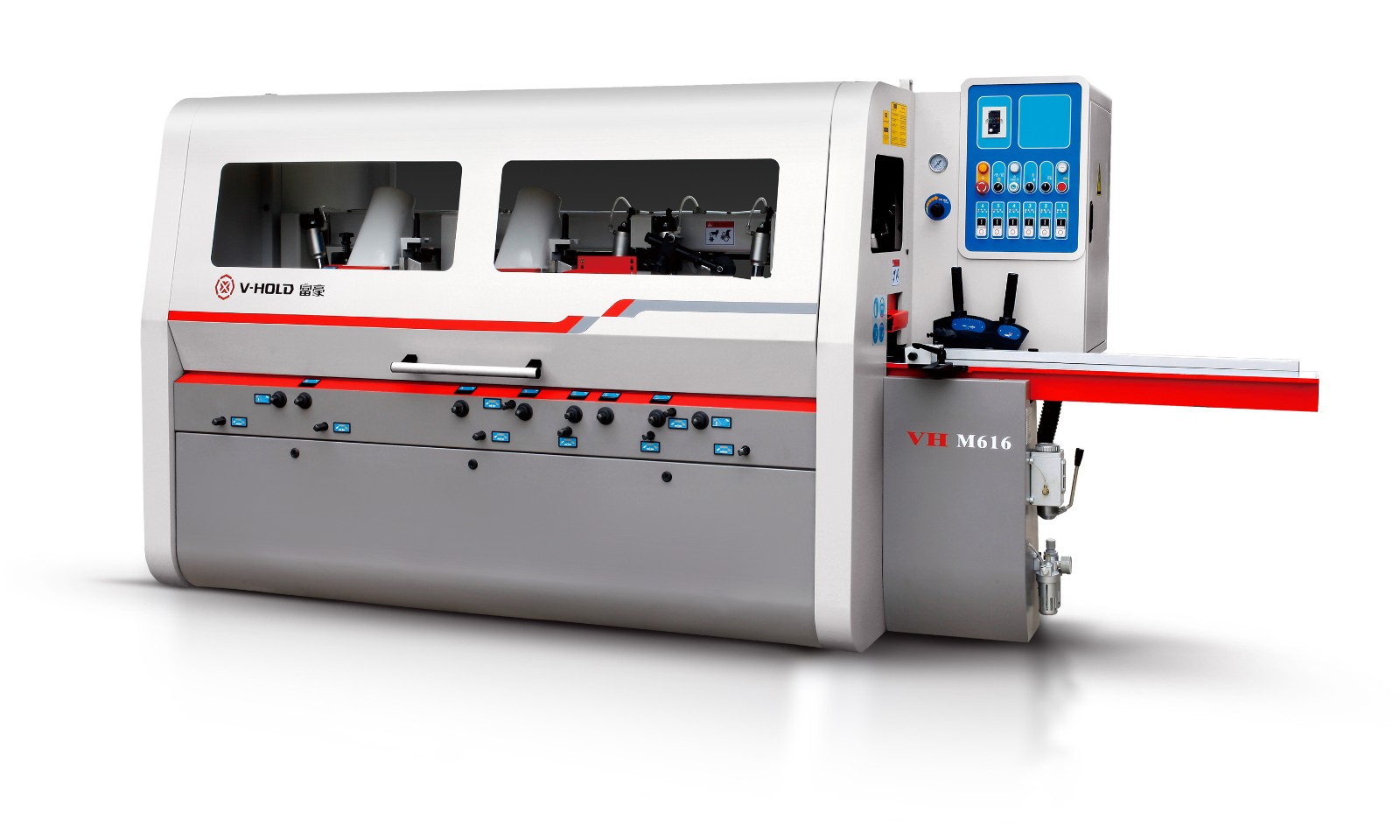

Are you looking for the best-selling 4 Sided Planer on the market? Look no further! V-HOLD Woodworking Machinery Manufacture Co., Ltd, located in the heart of Lunjiao town, is the leading woodworking machinery manufacturer in China. With more than 20 years of production experience with top-quality four-sided planers, V-HOLD has established itself as the go-to brand for woodworking professionals worldwide.

Their commitment to perfection is evident in their flagship product, the 4-side Planer. This versatile machine allows users to shape and mold wood from all four sides, granting them the freedom to create intricate designs and achieve precise dimensions. With its advanced features and user-friendly interface, the 4-side Planer from V-HOLD is a must-have for any serious woodworking enthusiast.

V-HOLD 4 sided Planer Moulder - VH-M521GH (High-Speed Moulder)

Introducing the V-HOLD 4 Sided Planer Moulder - VH-M521GH, the ultimate solution for high-speed wood molding. This powerful machine is designed to effortlessly transform raw timber into finely crafted and precisely shaped pieces with its advanced four-sided planing capabilities. With exceptional speed and accuracy, the VH-M521GH ensures consistent and flawless results, making it an essential tool for woodworking professionals seeking efficiency and excellence in their craft.

Advantages of Using a 4 Sided Planer

A 4 Sided Planer offers a range of benefits that enhance efficiency, precision, and productivity in woodworking and construction projects. Let's explore them one by one.

1. Enhanced Efficiency

The capacity to process wood on all four sides at once is one of the main benefits of a 4 Sided Planer. When compared to conventional techniques that demand many passes and corrections, simultaneous machining saves a lot of time and work. As a result, producers may considerably boost production, meet strict deadlines, and simplify operations.

2. Unparalleled Precision

The 4 Sided Planer ensures consistent and accurate results. The use of multiple cutter heads, each with specific functions, allows woodworkers to achieve precise dimensions, profiles, and surface finishes. This level of precision is especially valuable when producing furniture, architectural moldings, flooring, and other wood products that demand uniformity and quality.

3. Versatility

The 4 Sided Planer gives a tremendous amount of versatility because it can carry out a number of machining operations in a single pass. To meet various design needs, woodworkers can produce various profiles, including beads, coves, chamfers, and decorative patterns. This adaptability broadens the range of products that can be produced and creates new creative opportunities.

4. Waste Reduction

The 4 Sided Planer reduces waste by maximizing the use of the material. It maximizes the useful yield from each piece by successfully eliminating flaws and accurately measuring the wood. By minimizing its negative effects on the environment, this waste reduction not only improves profitability but also encourages sustainable practices.

Conclusion:

The 4 Sided Planer has become an indispensable tool in modern woodworking, providing manufacturers with the means to achieve superior precision, efficiency, and versatility. By simultaneously processing all four sides of a piece of wood, this machine has transformed the way the wood is shaped and refined. Its impact on the industry is profound, enabling woodworkers to meet market demands effectively while minimizing waste. As the woodworking industry continues to evolve, the 4 Sided Planer stands as a testament to innovation and progress in the pursuit of excellence.

Copyright © 2020 V-hold Woodworking Machinery Manufacturing Co., Ltd. | All Rights Reserved Sitemap