V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

A four-sided planer machine or a four-sided planer molder or four-sided planer, is a woodworking machine. It boasts versatile designs usable for the simultaneous shaping and smoothing of wooden boards or beams. Design is to suffice for the removal of material evenly and precisely. It results in uniform planed and dimensioned pieces.

The four-side planer is purposefully designed to streamline and automate the planing and sizing lumber process. It can save considerable time and effort as compared to manual planing. This machine is commonly used to transform uneven and rough timber into smooth, and precisely dimensioned pieces in diverse conditions.

Four-sided planer machines play crucial in streamlining woodworking operations with efficiency and the ability to process large timber quantities. Use of furniture manufacturing, flooring production, cabinetry, joinery, etc. is common. In this, we will also explore the best four side molder products manufactured by V-Hold. V-Hold is a prime woodworking machinery manufacturer serving since 1996. Let's explore quality, safety, and other aspects of the best four-side planers.

VH-616A is a heavy-duty four-sided planer molder machine. It is designed to perform small to large-scale woodworking operations.

● High precision spindle 6200r/min

● Independent motor starts with a separate opening and closing spindle.

● Weight-resistant cutting gearbox

● Working width(mm) 25~160

● Working thickness(mm) 8~120

● In-feed-table length (mm) 1500

● Feeding speed(m/min) 6~36

● Air pressure 0.6 (Mpa)

● Overall dimensions(mm) L3750*W1550*H1720

VH-616A has several benefits including:

● It is an ideal product for ripping large panels.

● You can achieve the consistency in planks required or wanted.

● It is used to achieve precise dimensions in cutting wood pieces.

● You can use high volume woods in consistent size to manufacture furniture.

● Its use for solid wood is common.

● This is a power pack product to rip multiple pieces simultaneously.

● Versatile design makes it perfect across diverse woodworking applications.

● You can get precise and accurate cuts.

● Width is adjustable according to specific conditions.

● Easy to work on small material.

● Concerning features, it can be expensive.

VH-M618HA is a four-side molder woodworking machine that boasts a high-efficiency permanent magnet motor feeding system, high precision spindle, and much more. Let's explore more features.

● Double front and bottom planer structure in rough planing and fine planing.

● High-speed spindle boasting 8000r/min rotational speed.

● Cemented carbide was sprayed on the work table to make it durable.

● Super heavy cutting gearbox.

● Three positional equipment to stop the device in an emergency.

● A feeding conveyor to ensure the smooth passage of short material.

● Feeding double active wheel to provide idler pressure.

VH-M618HA is a well-designed product to achieve accurate and consistent outcomes. Below are the typical usages of the four-sided molder machine.

● Great for ripping solid wood.

● Cut fireboard and other furniture in small cuttings for desired polishing.

● Perfect choice for a solid wood picture frame and kick line.

● Get intricate designs done with the required thickness and width.

● High-efficiency permanent motor with high feeding speed.

● Surface finish of the base surface with smoother feeding with double front and bottom planer structure.

● High-precision spindle to speed up operation.

● Durable because of sprayed cemented carbide.

● Perfect for raw wood processing in the jigsaw industry.

● May require specific training.

● Space requirements

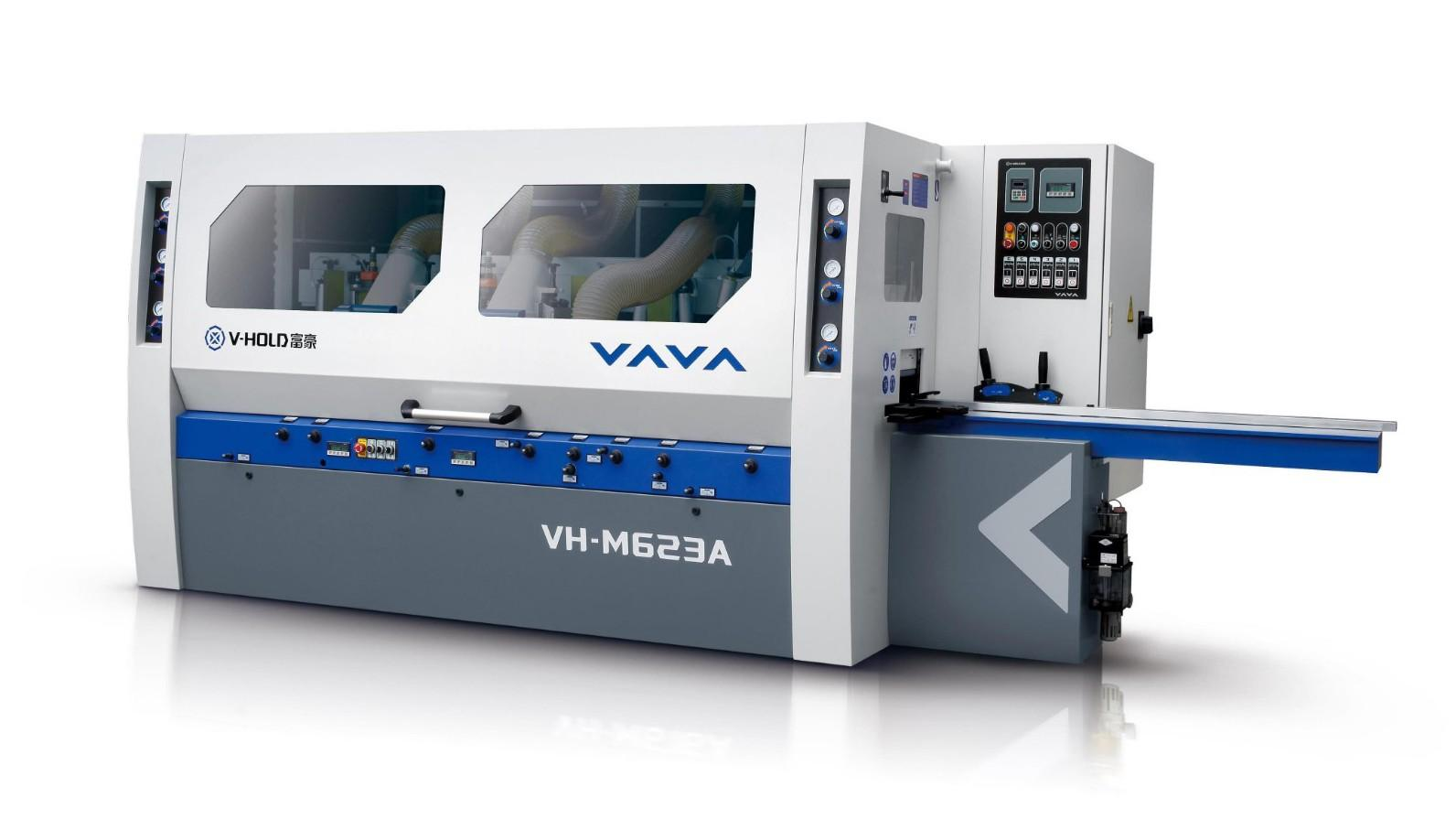

VH-623A is a 23A series four-sided planer used for hardwood lines. It is perfectly suitable for cutting large volumes in one-time four-sided molding processing. Let's discuss this in more detail.

● High rotational speed 6200r/min.

● High-precision spindle.

● The independent motor starts according to the actual processing configuration.

● Weight-resistant cutting gearbox.

● Equipped on three positions to ensure a stop device in an emergency.

● Standard short material device.

● Full range frequency conversion feeding system

VH-623A is a top-quality four-side molder machine that brings absolute peace of mind to professional woodworkers.

● It is used for hardwood lines.

● A high-speed feeding system makes molding processing a breeze.

● Three pieces of equipment to ensure optimal security so workers can perform cutting and profiling with peace of mind.

● High-precision spindle to get accurate and consistent results throughout the project.

● Takes less space.

● Incredibly secure and reliable to perform diverse operations.

● Full range standard frequency conversion feeding system.

● High rotational speed

● Quickly liftable short material device

● Tested under an air-conditioned environment and is supported by SKF bearing cutter shaft

● It may cost high on initial investment

VH-626V is a heavy-duty four-side molder woodworking machine to produce rip wood and achieves precise dimensions and accuracy in work. Below are different features, uses, and pros and cons.

● Max working width 260mm

● Working thickness(mm) 10~200

● In-feed-table length(mm 1970

● Feeding speed(m/min) 6~36

● Spindle revolution speed(r/min) 6500

● Air pressure(Mpa) 0.6

● Overall dimensions(mm) L5000*W2000*H1950

● Weight(kg) 4500

● Air volume 12800m³/h

VH-626V is a four-side molder that boasts features that make it practicable for a diverse pool of uses.

● Great product to achieve accuracy and consistency in manufacturing desktops.

● Best to achieve intricate design requirements of Europe windows.

● Get the required thickness and width in handrails.

● Precisely ordered internal structure.

● Smooth and powerful feeding with 6 lower rollers.

● Pneumatic compression system.

● Two sets of feeding systems in the upper shaft for smooth and forceful cutting of large volumes.

● More stable material pressing

● Thickness could have been improved

VH-M521GH is a superior design with superior material to deliver top-notch performance. It boasts speed that makes working on small to large-scale projects a breeze. Let's get into more detail about the product.

● Working width 25-210

● Working thickness 25-160

● Working table length 1970

● Feeding speed 10-60

● Main spindle revolution 7000

● Overall dimensions L3800*W1650*H1900

● Suttle 3500

● Highest feeding speed 60 m/min

VH-M521GH is designed to deliver quality designs or profiles and rip woods to achieve the required thickness, width, and accuracy.

● Speedy feeding speed helps achieve accuracy and consistency at a faster rate in small to large-scale operations.

● Perfect solution for woodworking professionals to take on large amounts of wood material.

● Takes less time to process wood.

● It reduces labor costs with improved efficiency.

● Auto feeding to ensure the system is fed at high speed.

● Excellent working width and thickness.

● Use of superior quality material in production.

● Professional solution for ripping large wood.

● Less labor cost on an efficient improved work

● May have a high initial cost

21 Series is a four side moulder solution for medium processing cutting capacity strips, MDF, etc. It boasts the quality you need in your armor of woodworking machinery.

● Working width: 25-210mm

● working thickness: 8-150mm

● working table length: 1970mm

● Main shaft revolution: 6000r/min

● Air pressure: 0.6MPa

● feeding speed: 6-36m/min

● Main shaft diameter: 40mm

This machine is the solution to many of the functions that woodworking operations need to meet.

● You can cut MDF and HDF strips.

● It is used to cut solid wood furniture and square boards.

● Processing medium-cutting capacity strips is a breeze.

● Perfect for heavy-type operations.

● Maximum working thickness and width.

● High rotational speed.

● No power loss because of the heavy cutting gearbox nourishment wheel.

● No roughness on the finished surfaces.

● Smooth feeding of the short material

Four Side Moulder Machines have several benefits including precise thickness, low time, saving on labor, and more. Woodworkers are efficient at enhancing woodworking efficiency and productivity. All the reviewed products boast all these applications through an assembling of top-notch features.

Choosing the right machine is crucial to achieve optimal results. You should consider factors like machine capacity and size, power and motor strength, upper cutter head configuration, and safety features before purchasing. That's how you can get whatever you are expecting from these products. They boast features to elevate craftsmanship, improve productivity, and harness outstanding results. Embrace the capabilities V-Hold products possess. They are equipping woodworking machinery with features that you need to achieve desired outcomes with minimal effort.

1. What are the specifications of four side molder woodworking machines?

The Four Side Planer Machine boasts versatile design equipping with multiple spindles. It comes in a motor combination that drives the cutting blades and feed rollers. The machine features precise adjustment options to control the depth and thickness of the planed wood.

2. Can I adjust the feed rate on the side planer machine?

Yes, feed rate settings are customizable. Woodworkers can control the wood-feeding speed. It helps to garner the desired finish and characteristics of wood processing.

3. What are the maximum and minimum handleable thickness that the machine can handle?

These machines can handle various wood thicknesses. Thickness depends on the type of model and manufacturer. Refer to the machine's specifications or inquire manufacturers about.

4. Are feed rollers optional or included in the model?

Feed rollers are typically part of the standard model of a four-side molder machine. These rollers are extremely important in feeding the wood through the machine for planning. However, you should confirm whether feed rollers are optional or included in the purchase.

5. Is shipping available to the USA and European countries?

Shipping is available in the USA and some European countries. However, you should verify shipping options and associated costs with the original product cost. Cost can vary depending on specifications, diameter, model, and other features. Inquire price of the model directly from the manufacturers. If you're getting through a supplier, make sure to obtain the quota of the accurate price of the four-sided molder machine。

Copyright © 2020 V-hold Woodworking Machinery Manufacturing Co., Ltd. | All Rights Reserved Sitemap