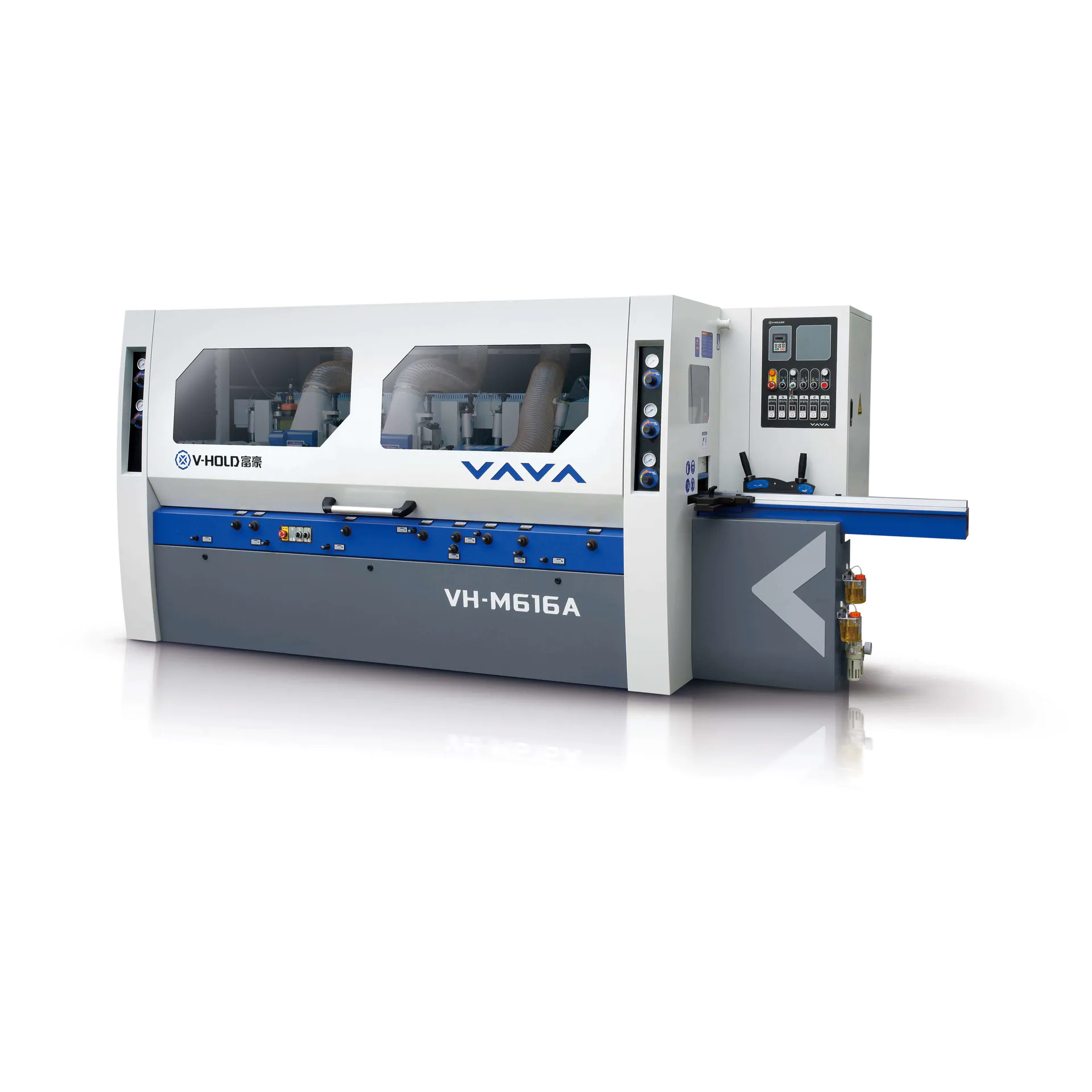

VH-M618HA HIGH SPEED HEAVY DUTY FOUR SIDE MOULDER

VH-M618HA is mainly used for 4 sided moulding processing of wood products'raw material. It can meet the need of raw wood processing in the jigsaw industry.

Product features:

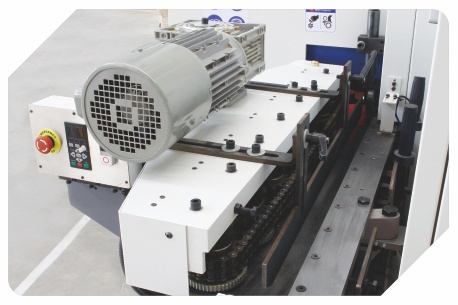

1.The full range of products are equipped with high efficiency permanent magnet motor feeding system, feeding speed 15-100m / min;

2.Double front and bottom planer structure, rough planing and fine planing are carried out on the wood bottom surface successively to ensure the surface finish of the base surface while ensuring a smoother feeding;

3.High precision spindle, rotational speed 8000r/min ;

4.The work table is sprayed with cemented carbide for durability;

5.Self-developed super heavy cutting gearbox;

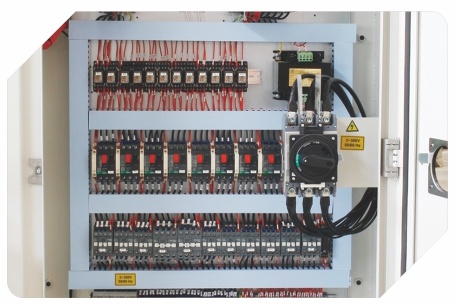

6.Equipped with 3 positions emergency stop device, install open door cover power off and feed port limit high limit switch.

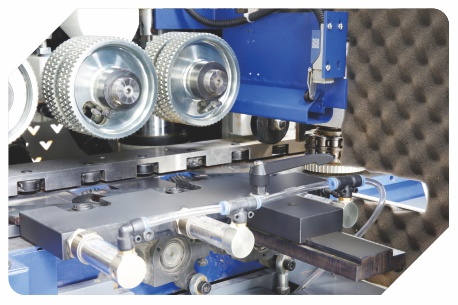

The side pressure wheels are all pressed by cylinders, and the pressure can be adjusted separately. The pressure setting is convenient. Excellent feeding performance.

The side pressure wheels are all pressed by cylinders, and the pressure can be adjusted separately. The pressure setting is convenient. Excellent feeding performance. A feeding conveyor is installed on the side of the worktable to ensure the smooth passage of short materials.

A feeding conveyor is installed on the side of the worktable to ensure the smooth passage of short materials. Equipped with two front and bottom planing cutters, the rough planing and fine planing processes are completed successively, which effectively ensures the flatness of the datum, maximizes the utilization of material value, and ensures the smooth feeding of the back processing.

Equipped with two front and bottom planing cutters, the rough planing and fine planing processes are completed successively, which effectively ensures the flatness of the datum, maximizes the utilization of material value, and ensures the smooth feeding of the back processing.