V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

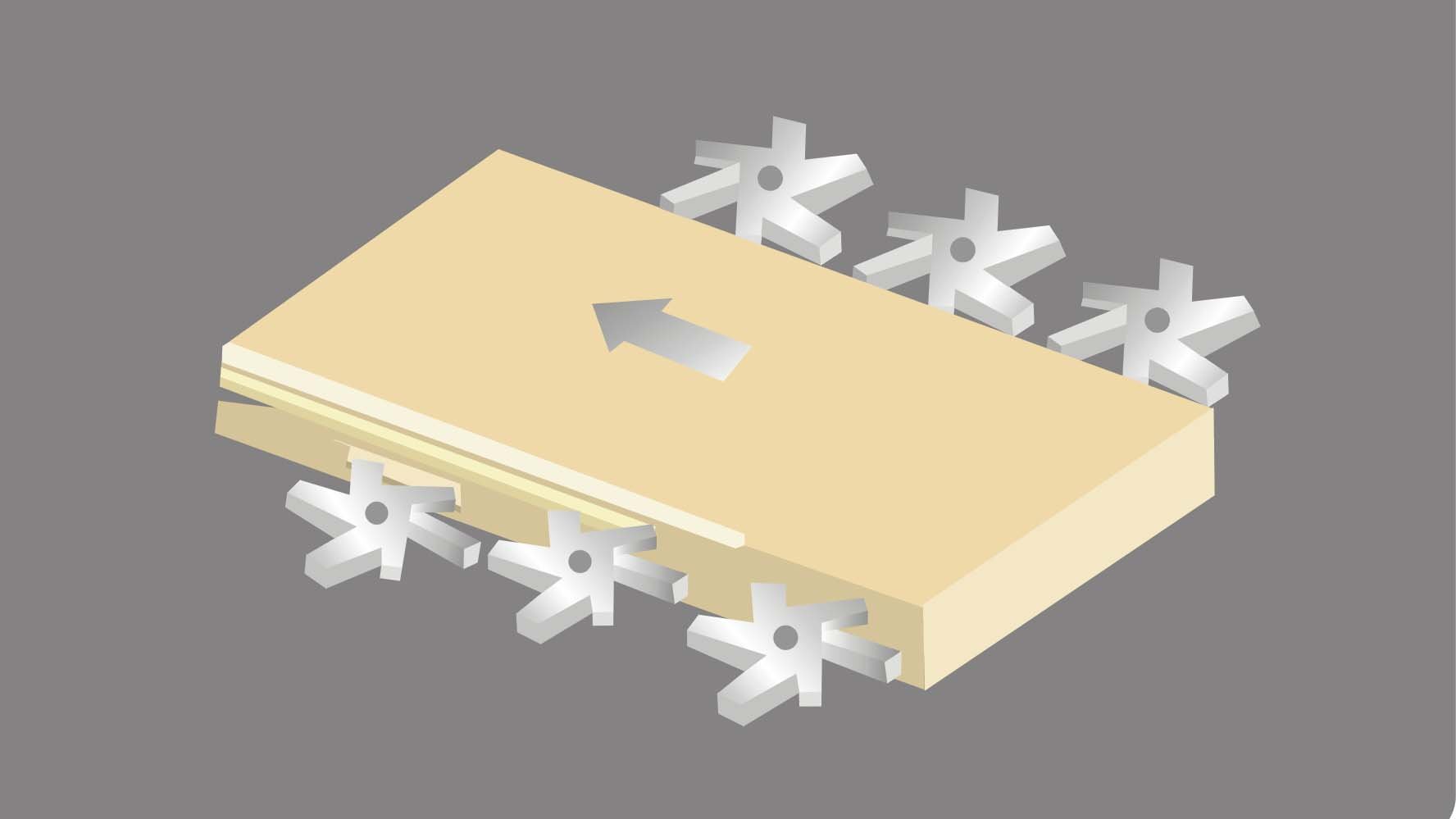

The floor plates are sent into the runnig bearings of the machining track with the material feeder and delivery rubber rollers, and the guide rails are made with extra hard materials, ensuring the machining precision.

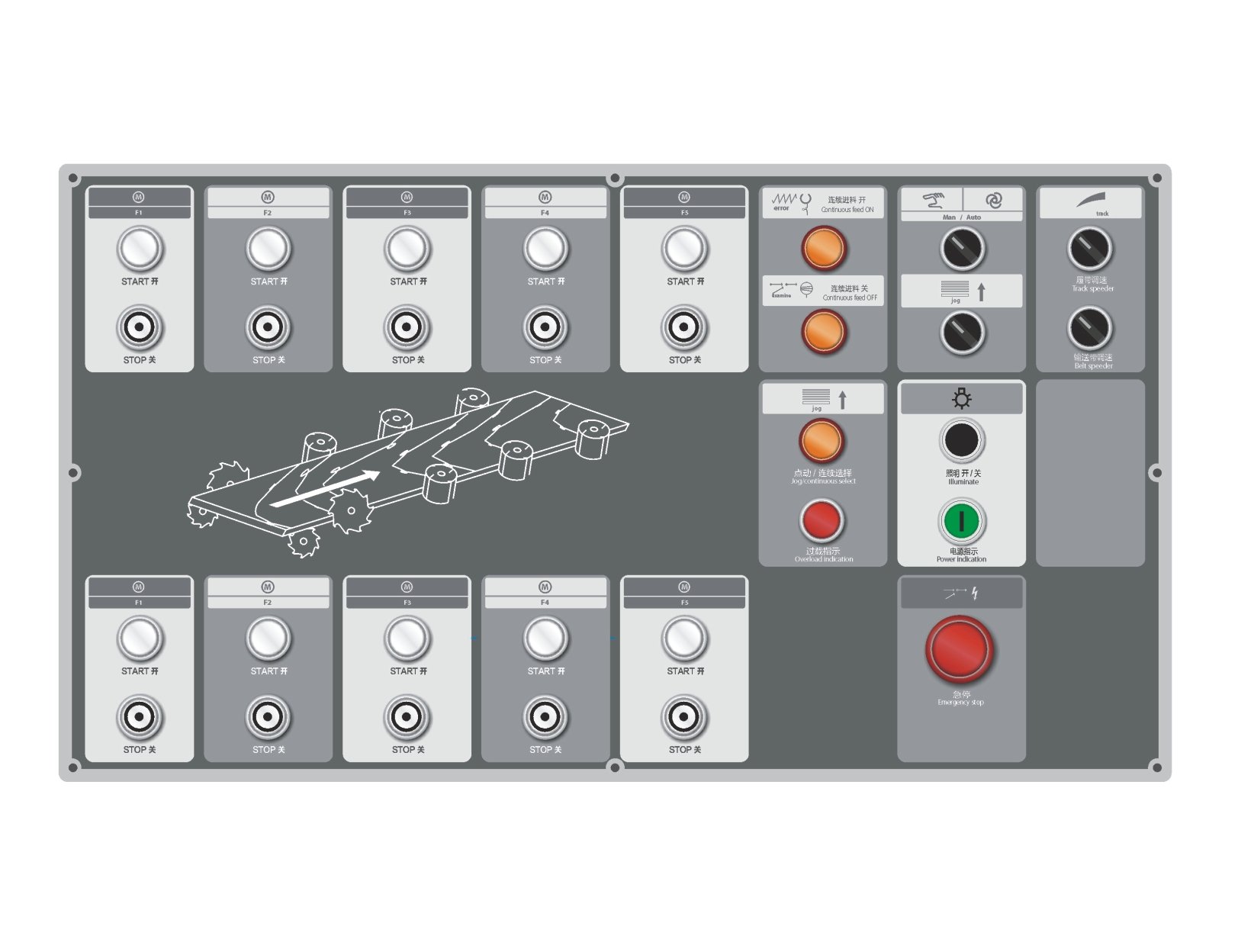

With the imported PLC and the frequency conversion device, the double-end miller works very smooth.

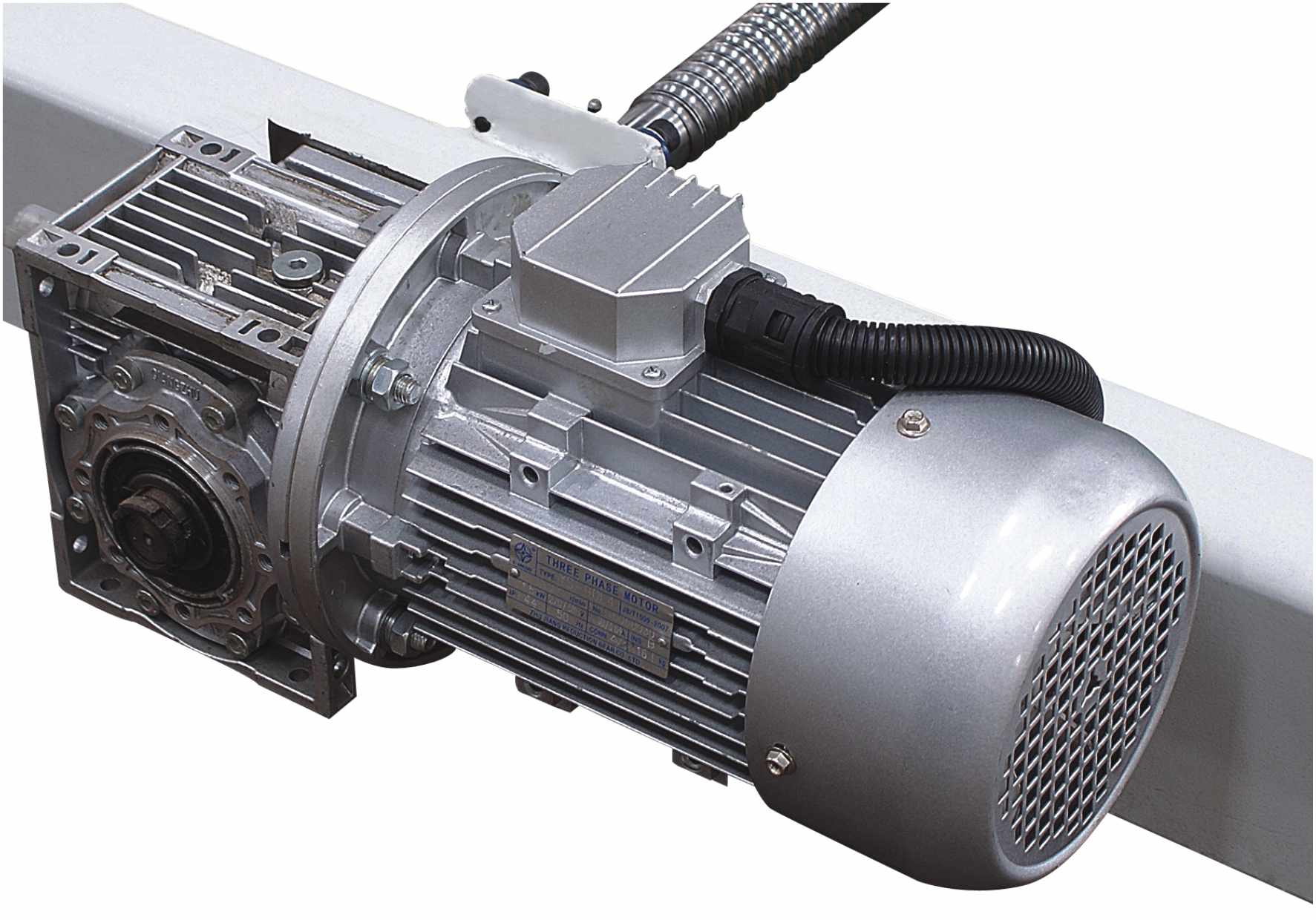

Forcefully feeding decelerator features speed regulation by frequency inverter.

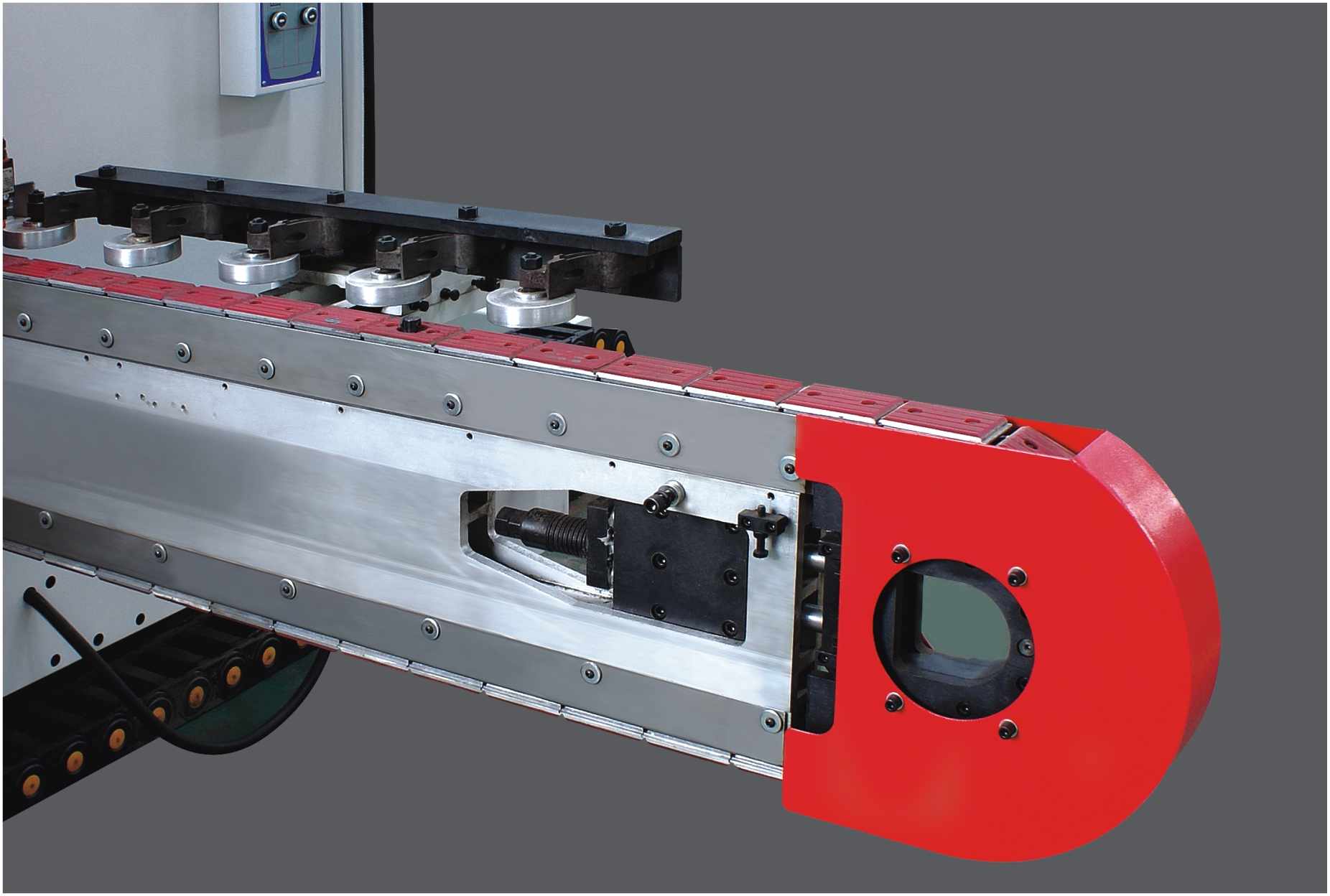

With the built-in cleaning brush wheel, the dust inside the track guide rail can be cleaned automatocally.

With the compact sawing shaft mechanism, the cutters are closed to the pressing belt, ensuring the machining stability.

Structure acting as ball-screw makes machine have more accurate adjustment.

| Specification and Model | MB2626D |

| Feeding speed (m/min) | 6-30m/min |

| Max. Working wiidth (mm) | 800mm |

| Min. Working width (mm) | 100mm |

| Max. Working length (mm) | 2600mm |

| Min. Working length (mm) | 300mm |

| Max. Working thickness (mm) | 60mm |

| Max. Working thickness (mm) | 10mm |

| Vertical and click shaft revolution (r/min) | 6000/6000-8000r/min |

| Vertical and click shaft diameter (mm) | Φ40mm |

| Vertical milling cutter diameter (mm) | Φ160-200mm |

| Click milling cutter diameter (mm) | Φ180mm |

| Feeding rubber roller diameter (mm) | |

| Vertical spindle motor power (kw) | 3kwx6sets |

| Card buckle spindle motor power (kw) | 2.2kwx2sets |

| Feeding motor power (kw) | 3kw |

| Elevatory motor power (kw) | 0.75kw |

| Lifting motor power (kw) | 0.75kw (width openning motor) |

| Total power (kw) | 26.9kw |

| Air pressure (MPa) | 0.6MPa |

| Physcial dimension (mm) | 3450x2600x1670mm |

Copyright © 2020 V-hold Woodworking Machinery Manufacturing Co., Ltd. | All Rights Reserved Sitemap