V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

Molder woodworking machines are versatile tools to produce intricate trims, moldings, and designs. These machines boast features to produce consistent and precise profiles enhancing the overall quality and aesthetic appeal of the woodwork. They are revolutionizing the woodworking industry through the way moldings and trims are produced.

Consistency in molding designs is an essential component of large-scale manufacturing or architectural projects that woodworkers can achieve with these machines with optimal accuracy and precision. These machines not only streamline production but also provide creative freedom to artisans and craftsmen. They enable woodworkers to bring their valuable design ideas to life with precision and finesse.

Unbelievable benefits of woodworking molding machines have led to making these machines indispensable for both professionals and hobbyists. This blog article is to address concerns with the best product manufactured by V-Hold. It is a name of quality that they have devoted themselves to offering to provide quality in their woodworking molding machines that customers have deserved since 1996. Let’s explore the quality they offer in their products.

VH-MJ164 Single/Multi is a woodworking machine that provides the molds and cuts you need with high precision.

Features● Main spindle revolution (r/min) 3000 ● Spindle diameter (mm) Φ 50.8 ● Feeding speed (m/min) 11-26 ● Max. working thickness (mm) 120 ● Cutting width (mm) 660 ● Working table sizer (mm) 2000>x1160 ● Dimension (mm) 2300x1200x1500 ● Max. Saw blade diameter (mm) Φ 455 ● Max. Working width (mm) >Φ 355 | UsesVH-MJ164 provides several benefits that lead to optimized accuracy and consistency in a short period. ● This machine is used to cut large boards used in construction works. ● You can use it to cut wood pieces used to make furniture. ● Cutting structural components in consistent width is a breeze. ● You can produce straight cuts parallel to wood grain. |

Pros● 8 sets of pressing wheels to ensure optimum stability. ● Straight, smooth, and precise with machine with wide working surface. ● Automatic lubrication of all major parts to extend the life of the device. ● Sturdy construction with adjustable width to deliver accurate and precise cuts | Cons● The machine might be expensive considering the level of service it provides |

VH-626V is another best name in the four-side molder woodworking machines that work wonders for woodworkers. Let's discuss more about the product in detail.

Features● Working width(mm) 25~260 ● Working thickness(mm) 10~200 ● In-feed-table length (mm 1970 ● Feeding speed(m/min) 6~36 ● Spindle revolution speed(r/min) 6500 ● Air pressure(Mpa) 0.6 ● Overall dimensions(mm) L5000*W2000*H1950 ● Weight(kg) 4500 ● Air volume 12800m³/h | UsesVH-626V is a solution for most woodworking operations. You can use it in: ● Heavy-duty large boards for construction. ● Rip woods for manufacturing furniture. ● Use it for intricate designs or profiles. ● High feed speed to work on large volumes smoothly and forcefully. ● Pneumatic compression to press material stably. |

Pros● Ordered structure with great precision. ● Smooth feeding to get things done speedily and smoothly. ● Two sets of feeding systems for smooth and forceful wood cutting. ● Stable material pressing. | Cons● Can be expensive considering a wide range of quality features. ● May require maintenance |

VH-MJ163 Single/Multi Rip Saw is a woodworking tool that offers features to take on a diverse range of tasks. Let's explore different aspects of the product.

Features● Cutting width (mm) 410 ● Main spindle revolution (r/min) 3300 ● Spindle diameter (mm) >Φ 50.8 ● Feeding speed (m/min) 7-19 ● Max. working thickness (mm) 80 ● Max. Saw blade diameter (mm) >Φ 400 ● Lubricate pump motor power (w) 20 ● Working table sizer (mm) >1720>x912 ● Dimension (mm) >1950x1920x1300 ● Net weight (kg) 1100 | UsesThis is a diversely constructed woodworking machine that provides various benefits. ● Intuitive design to rip large wood panels or boards. ● Use for producing planks of consistent width. ● You can get precise dimensions of wood pieces suitably. ● Perfect for cutting wood for manufacturing furniture. ● Cut high volume in a consistent size |

Pros● Securely work on large cutting volume with a blade under the working surface. ● Stable functioning in the conveying process with the 8 sets of pressing wheel devices. ● Precise and smooth cute with the double brack chain conveyor. ● Automatic lubrication of all major parts extends the life of the product. ● Customizable width to work on specific projects. | Cons● May require training and maintenance services. |

VH-ML9321 is a multiple rip saw molder woodworking machine that brings new essential energy to woodworking projects. You can switch swiftly on professional operations with this machine.

Features● Top spindle rotation rate 6000r/min ● Bottom spindle rotation rate 6000 r/min ● Max. working width 210mm ● Max. working thickness 70mm ● Feeding speed 4-18m/min ● Top spindle diameter 40mm ● Cutting spindle rotation rate 4000r/min ● Max. saw blade diameter 300mm ● Air pressure 0.6Mpa ● Dimension 3070×1230×1540mm | UsesVH-ML9321 is a molder woodworking machine that carries excellent features that make it a suitable option for work on various woodworking projects. ● It is used in the production of narrow strips or boards. ● The machine is used for precise planning to get a smooth and even surface. ● Use for accurate shaping and sizing of lumber is common. ● Sturdy construction gives the advantage to work on diverse tasks including furniture, floor, etc. |

Pros● You can open the lid to increase the width as the wood exceeds. ● High power helps to process wood to the desired thickness and width. ● Overall efficiency in ripping and planning functions. ● Achieve consistent and accurate dimensions throughout the project. ● Multiple functions save space to get the maximum things done with one piece of equipment. | Cons● May be expensive considering features. ● May require extra costs for maintenance |

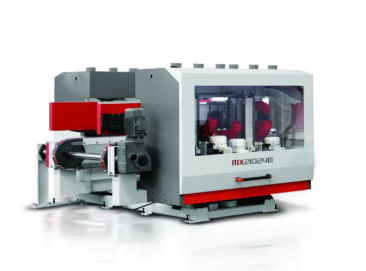

VH-MX21024B Double End Tenoner is a gem of a product that brings peace of mind to professional woodworking boasting a diverse pool of features. Let's dig into features, uses, and other aspects.

Features● The length from the feeding end of the top pressing beam to the dog is 800mm ● Swaying shaft rotation 2800 ● Bottom saw blade size 230mm ● Max. Working length 2400mm ● Min. Working thickness 10mm ● Max. Working thickness 25mm ● Feeding speed 6-30m/min ● Min. Working width 100mm ● Max. Working width 300mm ● Spindle speed 6000 ● Air pressure 0.6Mpa | UsesVH-MX21024B is a molder woodworking machine that boasts myriad features that make it a perfect choice for diverse woodworking applications. ● It is used for real wood and multilayer floors. ● The conveyor chain edition guide feed system provides high precision. ● Sturdy design to perform small to large-scale projects such as house construction and other architectural functions. |

Pros● High feeding speed to stay steadfast on the projects. ● Maximum working thickness and width to perform various woodworking operations. ● High spindle speed ● Powerful motor for speedier and more accurate cuts. ● Passive pressure on the strip ● Double linear guide | Cons● Maybe a high initial investment |

Incorporating a molder woodworking machine in your woodworking arsenal means enhanced craftsmanship and efficiency. You can recapitulate on wood molding machine benefits by choosing the right product.

A woodworking molder machine is a package of precision, versatility, time, and cost efficiency. Achieving consistent and accurate molding results becomes extremely easy tackling a variety of projects. Choose the right molding machine save time, and effort, and make additional revenue by working on a diverse range of projects.

Our reviewed products from the V-Hold company boast similar potent features that deserve to be a part of your woodworking arsenal. V-Hold has been serving customers with quality products since it was founded in 1996. Maximizing efficiency and productivity are guaranteed in quality precision and efficiency in diverse projects. Choose any product and enjoy cost savings and investment benefits in the long term.

What factors should I look for in a straight-line rip saw? Priorities safety when buying a straight-line rip saw to ensure maximum protection. The machine should have a chain block surface to minimize kickback risk. It controls the movement of the workpiece. Also, endure heavy-duty industrial motors for a smooth and reliable operation. With these features on the rip saw machine, professionals can have utter peace of mind. They can work free from worries injuries or accidents. |

What specifications do four side molder machines have? Molder Woodworking Machine is a versatile tool including four side planers. They feature multiple spindles. Motor combination drives cutting blades and feed rollers. You can control the depth and thickness of the planed wood with precise adjustable options. |

What are the different categories of equipment available in older woodworking machines? Wood molding machines are different in equipment depending on needs and preferences. Paner heads, cutter heads, variable feed speed mechanisms, and stands are some of the equipment used in different machines. Each category offers desired accuracy and precision in woodwork based on functionality and ways of usage. |

Can I adjust the feed speed in a wood molding machine? Yes, machines come with customizable feed speed settings. Control of feed speed is in your hand when wood passes through the machine in the molding process. You can achieve desired results based on specific requirements. |

How can wood molding machines save money for customers or buyers? Molder woodworking machines are versatile to benefit customers and buyers. Achieving efficiency and precision in shaping wood, and waste wood, and maximizing the use of resources is a breeze. You can create custom moldings in-house that can save costs on outsourcing work. You can also make additional money by taking on more projects. |

Copyright © 2020 V-hold Woodworking Machinery Manufacturing Co., Ltd. | All Rights Reserved Sitemap