Related Products

V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

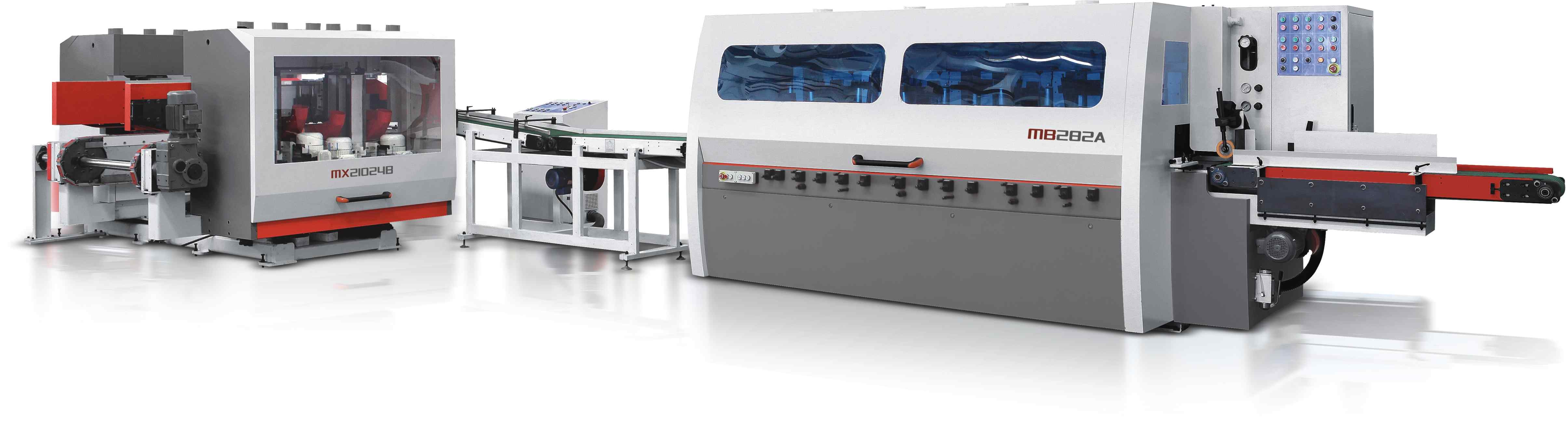

MB283A+MX21024B

| Specification and Model | MB283A | MB21024B |

| Max. Working wiidth (mm) | 300mm | 300mm |

| Min. Working width (mm) | 60mm | 70mm |

| Max. Working length (mm) | 2400mm | 2400mm |

| Min. Working length (mm) | 600mm | 400mm |

| Feeding speed (m/min) | 8-50m/min | 10-40m/min |

| Vertical and click shaft revolution (r/min) | 6000/6000-8000r/min | 6000/6000-8000r/min |

| Vertical and click shaft diameter (mm) | Φ40mm | Φ40mm |

| Vertical milling cutter diameter (mm) | Φ160-200mm | Φ160-200mm |

| Click milling cutter diameter (mm) | Φ180mm | Φ180mm |

| Feeding rubber roller diameter (mm) | Φ180x12units | |

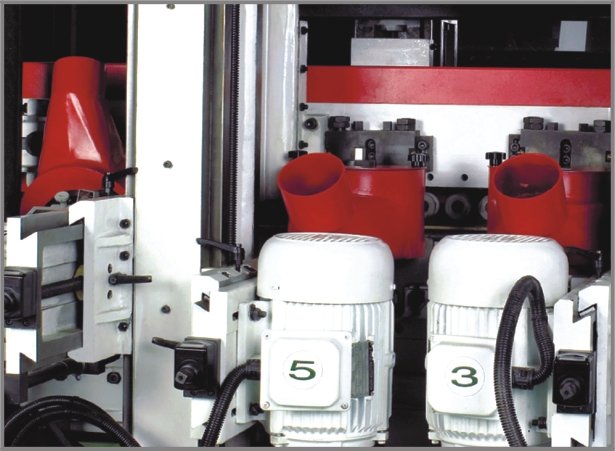

| Vertical spindle motor power (kw) | 4kwx4sets 3kwx2sets | 3kwx6sets |

| Card buckle spindle motor power (kw) | 2.2kwx2sets | 2.2kwx2sets |

| Feeding motor power (kw) | 5.5kw | 3kw |

| Elevatory motor power (kw) | 0.75kw | 0.75kw |

| Lifting motor power (kw) | 0.75kw | 0.75kw (width openning motor) |

| Total power (kw) | 35.4kw | 26.9kw |

| Air pressure (MPa) | 0.6MPa | 0.6MPa |

| Physcial dimension (mm) | 4880x1760x1810mm | 3450x2600x1670mm |

| MB2832 | MX21024B |

|  |

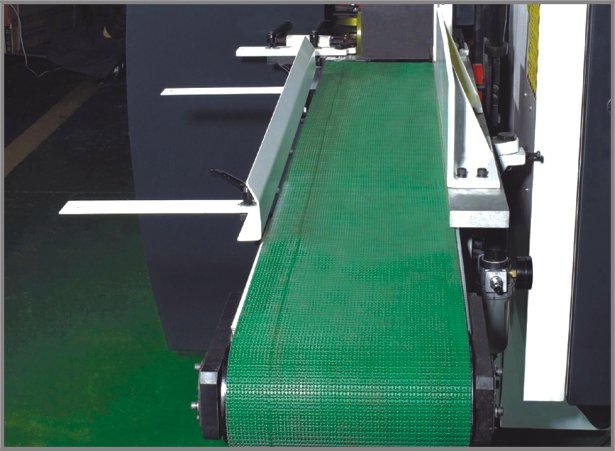

| With conveyor belt for material delivery, the labour intensity of the operators can be reduced. | With high speed electric driven shaft, the clamp cutter can be frequency cinverted within the scope of 6,000-8,000r/min. |

|  |

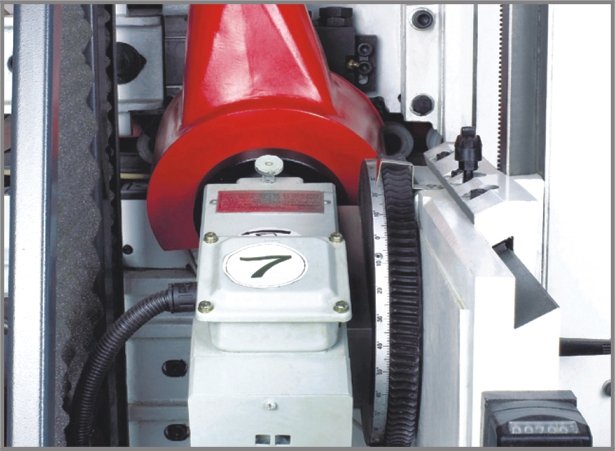

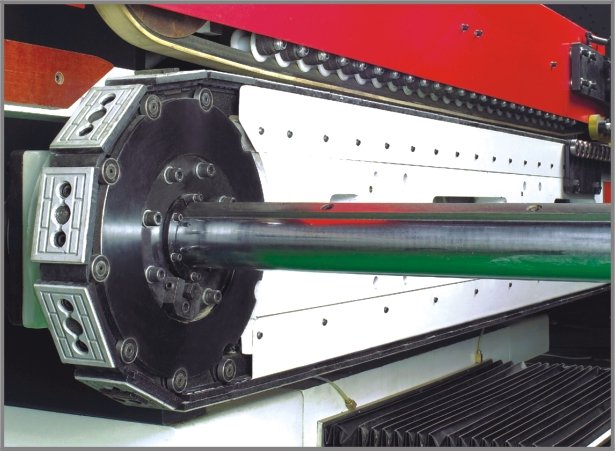

| The material pressing pressure is shown on the panel, which is quite convenient for direct veiwing. | The floor plates are sent into the running bearings of the machining track with the material feeder and delivery rubber rollers, and the guiderails are made with extra hard materials, ensuring the machining precision. |

|  |

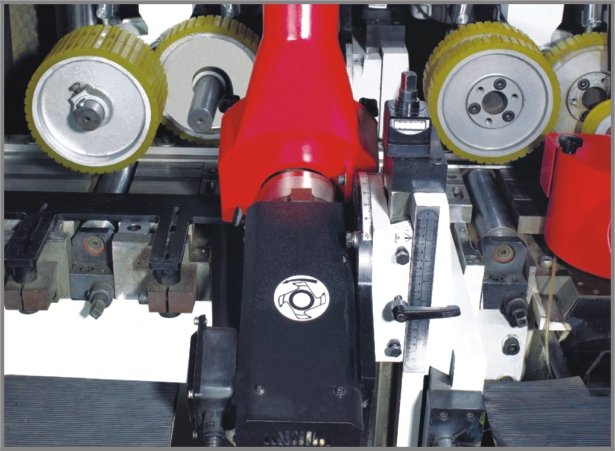

| With high speed electric driven shaft, the motor can be adjusted within the scope of 6,000-8,000r/min. | With the pressing plate and extra hard supplementary work table, the floor machining is very precise. |

Copyright © 2020 V-hold Woodworking Machinery Manufacturing Co., Ltd. | All Rights Reserved Sitemap