V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

Four side moulder VH-M521GH

M521GH High Speed Moukder has superior material delivery system. The highest feeding speed can up to 60m/min with automatic feeding system.

Professional solution for planning large amount of wood material. This machine can largely reduce processing time of wood, it improve efficiency and help reduce labour cost.

|  |  |  |

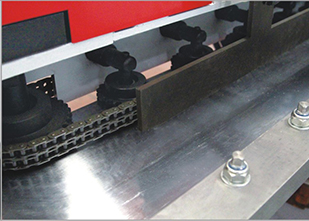

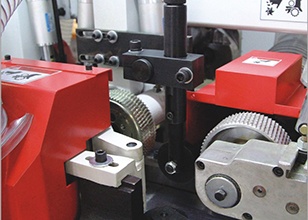

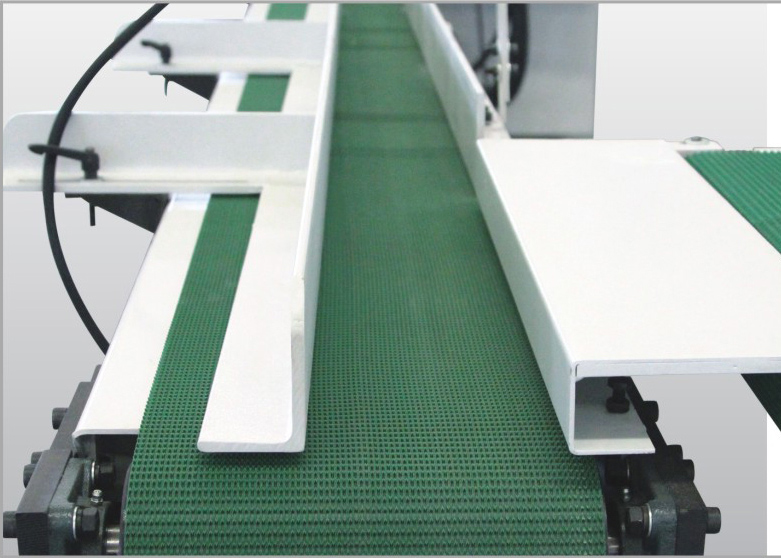

The side feeding mechanism which is installed in in-feed table can ensure the wood material to be fed continuously in high speed. | Equipped with gear case for short material to achieve continuously feeding and smooth cutting. | L conveyor can help workers reduce work intensity and achieve fast and efficient material in feed. | |

| VH-M521GH | VH-M416GH | ||

|---|---|---|---|

| specification | Working width | 25-210 | 25-160 |

| Working thickness | 8-140 | 8-120 | |

| Working table length | 1970 | 1500 | |

| Feeding speed | 10-60 | 6-60 | |

Main spindle diameter | Φ40 | Φ40 | |

| Main spindle revolution | 7000 | 7000 | |

| Air pressure | 0.6 | 0.6 | |

| Motor Power | 1st Lower Shaft | 5.5kw/7.5HP | 4kw/5.5HP |

| Right vertical spindle | 5.5kw/7.5HP | 4kw/5.5HP | |

| Left vertical spindle | 5.5kw/7.5HP | 4kw/5.5HP | |

| 1st Upper Shaft | 7.5kw/10HP | 5.5kw/7.5HP | |

| 2nd Lower Shaft | 5.5kw/7.5HP | / | |

| Feeding beam lifting | 0.75kw/1HP | 0.55kw/0.75HP | |

| Feeding motor | 5.5kw/7.5HP | 4kw/4HP | |

| Total power | 35.75kw/48.5HP | 22.05kw/28.6HP | |

| Cutter diameter | 1st Lower Shaft | Φ125 | Φ125 |

| Right vertiacl spindle | Φ125-Φ180 | Φ125-Φ160 | |

| Left vertical spindle | Φ125-Φ180 | Φ125-Φ160 | |

| 1st Upper Shaft | Φ125-Φ180 | Φ125-Φ160 | |

| 2nd Lower Shaft | Φ125-Φ200 | / | |

| Remark | Feeding wheel diameter | Φ140 | Φ140 |

| Dust outlet diameter | Φ140 | Φ140 | |

| Overall dimensions | L3800*W1650*H1900 | L3050*W1400*H1700 | |

| Suttle | 3500 | 2100 |

Processing technology

|  |  |  |

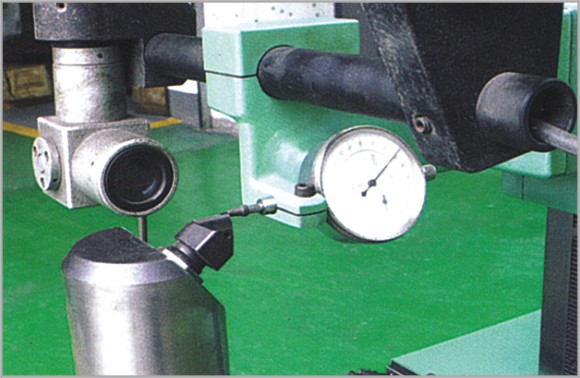

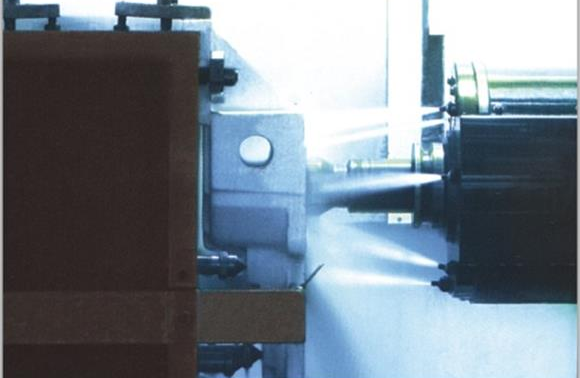

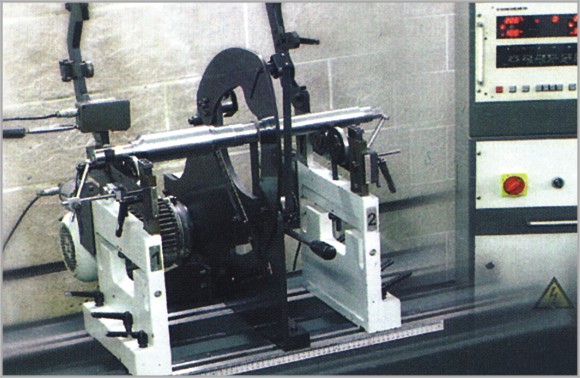

Bed height rigid integrated structure It is made of cast iron with damping property to ensure the smooth operation of cutter shaft and feeding system.Sophisticated processing equipment | Sophisticated processing equipment Meticulous and meticulous production to ensure that every part is nearly perfect! | Japan four axis linkage machining center All shaft frame, gear box and other accessories, the company is equipped with its own processing center to work, to ensure that the accessories precision | Spindle dynamic balance test Each spindle is equipped with imported SKF bearing to ensure the high precision and smooth operation of the cutter shaft Line. |

QUALIFICATION

Copyright © 2020 V-hold Woodworking Machinery Manufacturing Co., Ltd. | All Rights Reserved Sitemap