V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

High feeding speed 60m/min,max working width is 210mm with 5 spindles.

Four side moulder VH-M521GH

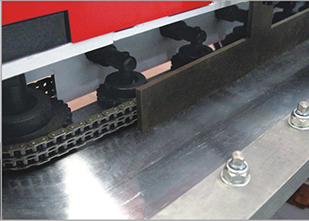

The side feeding mechanism which is installed in in-feed table can ensure the wood material to be fed continuously in high speed.

Auto feeding

Efficient

Adjustable speed

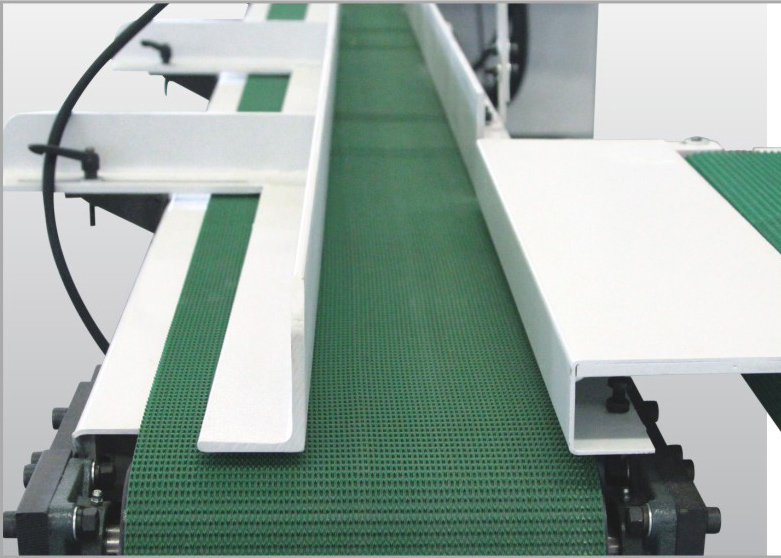

L conveyor can help workers reduce work intensity and achieve fast and efficient material in feed.

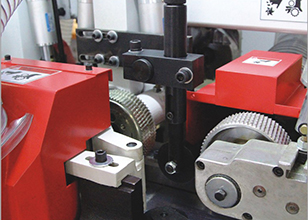

Equipped with gear case for short material to achieve continuously feeding and smooth cutting.

| VH-M521GH | VH-M416GH | ||

|---|---|---|---|

| specification | Working width | 25-210 | 25-160 |

| Working thickness | 8-140 | 8-120 | |

| Working table length | 1970 | 1500 | |

| Feeding speed | 10-60 | 6-60 | |

Main spindle diameter | Φ40 | Φ40 | |

| Main spindle revolution | 7000 | 7000 | |

| Air pressure | 0.6 | 0.6 | |

| Motor Power | 1st Lower Shaft | 5.5kw/7.5HP | 4kw/5.5HP |

| Right vertical spindle | 5.5kw/7.5HP | 4kw/5.5HP | |

| Left vertical spindle | 5.5kw/7.5HP | 4kw/5.5HP | |

| 1st Upper Shaft | 7.5kw/10HP | 5.5kw/7.5HP | |

| 2nd Lower Shaft | 5.5kw/7.5HP | / | |

| Feeding beam lifting | 0.75kw/1HP | 0.55kw/0.75HP | |

| Feeding motor | 5.5kw/7.5HP | 4kw/4HP | |

| Total power | 35.75kw/48.5HP | 22.05kw/28.6HP | |

| Cutter diameter | 1st Lower Shaft | Φ125 | Φ125 |

| Right vertiacl spindle | Φ125-Φ180 | Φ125-Φ160 | |

| Left vertical spindle | Φ125-Φ180 | Φ125-Φ160 | |

| 1st Upper Shaft | Φ125-Φ180 | Φ125-Φ160 | |

| 2nd Lower Shaft | Φ125-Φ200 | / | |

| Remark | Feeding wheel diameter | Φ140 | Φ140 |

| Dust outlet diameter | Φ140 | Φ140 | |

| Overall dimensions | L3800*W1650*H1900 | L3050*W1400*H1700 | |

| Suttle | 3500 | 2100 |

VIDEO CENTER

FAQ

◪ How many spindles of VH-M521GH?

5 spindles.

◪ What is the maximum working width?

210 mm.

◪ What is the fastest feeding speed?

60 m/min.

◪ What are the optional configurations?

L conveyor, it can help workers reduce work intensity and achieve fast and efficient material in feed.

◪ How to contact us?

Click here and contact us by email:v_hold@163.com

◪ What products can it process?

Planning large amount of finger joint wood and short pieces.

Copyright © 2020 V-hold Woodworking Machinery Manufacturing Co., Ltd. | All Rights Reserved Sitemap