V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

Woodworking machinery includes tools like planers, routers, and table saws. These machines provide precision and efficiency essentially needed in woodworking projects.

Woodworking machinery is perfect for crafting furniture or intricate wood designs. When you are buying these tools, consider factors such as accuracy, power, and safety features according to needs and preferences.

Before buying, know which brands are experienced and offering top-quality products on the market. V-Hold is one of the best woodworking machinery manufacturers. They have been serving efficiently since 1996. All the products adhere to European safety and quality standards including ISO 9001: 2000

This blog article covers the best professional woodworking machinery manufactured at the V-Hold, the advantages and disadvantages of these machines, and FAQs to introduce you to some more vital things you may have on your mind.

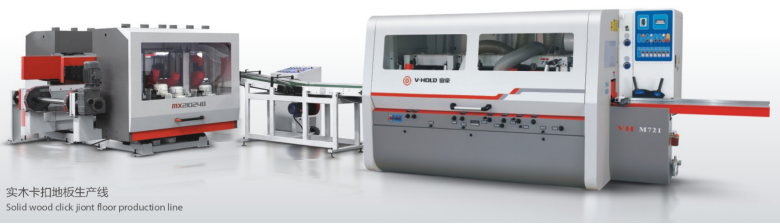

V-HOLD 4-Side Moulder VH-M721 features a powerful motor, high working thickness and width, Feeding wheel diameter, and more.

Features● 25-210mm working width ● 8-140mm working thickness ● 1970mm working table length ● 6-36m/min feeding speed ● Φ40 main shaft diameter ● 6500r/min main shaft revolution ● 0.6Mpa air pressure ● 3500 shuttle | Uses● VH-M721 carries features that you can use in nearly all the working procedures of solid wood. ● It is used for creating a piece of furniture. ● Vh-M721 is an excellent choice for woodworking art. ● It is used in operating conditions. |

Pros● Varying width and thickness make it great for a diverse range of applications. ● One machine can suffice for most procedures of solid wood. ● High feeding speed ● High main shaft revolution | Cons● More details should be added to the website. |

VH-623A is a professional woodworking machinery that features nearly all the features you need to work on hardwood. Let's discover more about the product.

Features● Independent motor start ● Standard device for short material ● High-precision spindle with 6200r/min rotational speed ● Efficient dust removal suction structure ● Feeder switch and scram switch for easy operation and adjustment. ● Feeding frequency inverter digital display ● Active feed supporting wheel | UsesVH-623A has several benefits to use it including the following: ● The high-precision spindle is great for intricate designs on wood. ● The quick liftable short material device makes working on short woods easier such as handrails or designing desktops. ● The liftable feeding roller helps change and adjust the knife easily so you won't go extra hard on profiling wood. |

Pros● Easy to operate and adjust with feeder switch and scram switch. ● Feeding frequency inverter digital display makes operations easy and saves energy. ● Active feed supporting wheel provides top roller pressure. ● Duct suction structure to remove dust efficiently. | Cons● Working thickness and width can be improved. |

VH-MB2045 is a highly solution-oriented product that is suitable for most woodworking operations.

Features● Working width 405mm ● Centralized lubrication system ● Feeding frequency inverter ● Digital display ● Thickness Quickset ● Gate magnetic induction switch ● Rear operation box to stop the machine in an emergency. ● Feeding device to prevent overload and give a safe operation. | UsesVH-MB2045 carries features that make it a viable option for safe and secure woodworking operations. ● A centralized lubrication system keeps it lubricated in more workloads such as at places where large woods are used. ● The digital display keeps you updated on different aspects to keep making necessary changes based on the working environment. ● Simple thickness settings allow you to produce intricate designs. |

VH-M618HA is a heavy-duty four-side molder that is most utilized in professional woodworking machinery. Below are features, uses, and other related things to know.

Features● Highly efficient permanent magnet motor feeding system. ● 8000r/min high precision spindle. ● Cemented carbide sprayed work table for durability. ● Super heavy cutting gearbox ● 3 positions emergency stop device ● Double front and bottom planer structure ● Concise operation panel ● Encryption belt cylinder side top | UsesVH-M618HA is a tool that boasts powerful features making it a viable option for most woodworking operations. ● It is used for processing wood products and raw materials. ● VH-M618HA is good for raw wood processing in the jigsaw industry. ● Separately adjustable side pressure wheels can make heavy wood conditions easy. ● A feeding conveyor makes working on small wood materials a breeze. |

Pros● Precise and orderly internal structure. ● Best for 4-sided molding processing of wood products raw material. ● Durable because of sprayed cemented carbide. ● High precision spindle ● High-efficiency permanent magnet motor ● Equipped with optimal emergency stop equipment. | Cons● Less diversity for maximum types of uses. |

16 Series carry features that are suitable for medium-duty functions. This should be on your list of professional woodworking machinery.

Features● 25-160mm working width ● 8-120mm working thickness ● 1500mm working table length ● 6-36m/min feeding speed ● 6000r/min main shaft revolution ● 0.6MPa air pressure ● Adjustable front and rear press plate | UsesThe 16 series has several usages in the medium-duty functions. ● It is good for softwood strips. ● You can cut medium-capacity strips. ● 16 series is great for glued laminated timber and square boards. |

Pros● The pressing wheel mechanism ensures smooth conveying ● of the short materials. ● Firmly pressable and adjustable front and rear plates. ● High working width and thickness. ● High-quality machining equipment | Cons● May be expensive |

Flawless Cutting Accuracy: Professional machinery brings flawless cutting accuracy to work. You can achieve optimal conditions of designs or profiles. This accuracy extra costs on wasted material.

Excels at Intricate Design: Working on intricate designs takes real effort. The chances of wasting wood are high. However, professional machinery can make such complex tasks easier.

Versatility: You can use professional machines to work on a variety of designs. Woodworkers can work on diverse tasks including cutting, shaping, and joinery. Now, a single piece of equipment can help design or profile easily.

Scalability: Professional machinery is easily adaptable to manage large workloads. Woodworkers can work on complex or large-scale projects with minimal effort.

Disadvantages of professional woodworking machinery should also be under consideration before purchasing machinery.

Electricity Dependent: Considering the size of woodworking machinery, most use heavy loads to operate. This is a big disadvantage that can cost high. You may also experience productivity issues in case of a power outage.

High maintenance Expenses: Machines can also require regular maintenance which can add up costs. Not everyone can pay for the regular inspections and repairs. So be prepared to consider high maintenance costs.

Woodworking machinery provides more benefits than our estimation. However, drawbacks should also be on your consideration. You may not afford some things such as regular inspections. So, don't forget to consider these disadvantages as shortcomings to prevent extra costs.

Professional woodworking machinery is designed purposefully to ensure users get a variety of desired outcomes. We also followed the same strategy to come up with the best products manufactured by V-Hold.

We assessed all the products carefully so you will have to look any further or face any unforeseen issues. Reviewed products carry features that you should have whatever product you are choosing.

V-Hold is an experienced manufacturer with decades of experience in the field. Their adherence to safety and quality standards are the glimpses you are likely to buy product needs and preferences accordingly.

This blog is an effort to help you reach an informed decision. Hope you will get the assistance from these products you need so you make an informed decision. In case of any queries or anything about the product you need to know, use email, phone, WhatsApp, etc. modes to get the necessary information.

Why should you check precision and efficiency?

Professional woodworking machinery is great for working on intricate designs. Precision brings the accuracy and consistency that are required in shaping. It makes wooden boards smooth. A more professional look that clients ask for becomes the highlight. Conversely, efficiency is to complete tasks quickly without requiring much effort. Woodworkers need professional machinery to maximize their productivity at optimum precision and efficiency.

How long does it take to deliver products?

The product is delivered in 30-45 days after the deposit is received. This is the company's policy for standard products. In case of special orders, it can take a longer period of delivery. For more, contact manufacturers directly for more information.

What is the after-sale service at the company?

The company offers a year warranty and lifetime maintenance service. You can contact the company directly for any technical problems. They also offer overseas repair and ongoing technical support.

How can I learn about the latest price and model details of products?

You can inquire about the product by messaging on the bottom left. The company will reach out to you with details. You can also contact the customer service team directly using email and phone. Online chat facility is available to contact via QQ, Weixin, WhatsApp, skype, etc.

Copyright © 2020 V-hold Woodworking Machinery Manufacturing Co., Ltd. | All Rights Reserved Sitemap