V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

VH-M618HA HIGH SPEED HEAVY DUTY FOUR SIDE MOULDER

VH-M618HA is mainly used for 4 sided moulding processing of wood products'raw material. It can meet the need of raw wood processing in the jigsaw industry.

Product features:

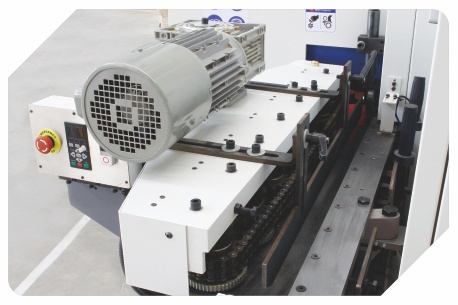

1.The full range of products are equipped with high efficiency permanent magnet motor feeding system, feeding speed 15-100m / min;

2.Double front and bottom planer structure, rough planing and fine planing are carried out on the wood bottom surface successively to ensure the surface finish of the base surface while ensuring a smoother feeding;

3.High precision spindle, rotational speed 8000r/min ;

4.The work table is sprayed with cemented carbide for durability;

5.Self-developed super heavy cutting gearbox;

6.Equipped with 3 positions emergency stop device, install open door cover power off and feed port limit high limit switch.

Wood sample of processed products

Machine function

The electric pump automatically lubricates the work table to improve the smoothness of feeding. Automatic lubrication pump is added to thefeed roller shaft

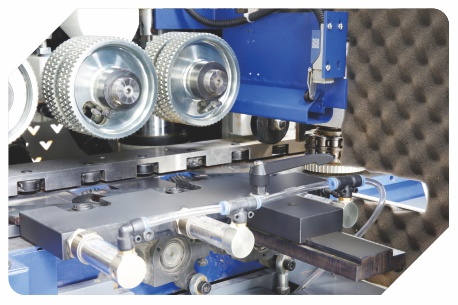

The side pressure wheels are all pressed by cylinders, and the pressure can be adjusted separately. The pressure setting is convenient. Excellent feeding performance.

The side pressure wheels are all pressed by cylinders, and the pressure can be adjusted separately. The pressure setting is convenient. Excellent feeding performance.

A feeding conveyor is installed on the side of the worktable to ensure the smooth passage of short materials.

A feeding conveyor is installed on the side of the worktable to ensure the smooth passage of short materials.

Equipped with two front and bottom planing cutters, the rough planing and fine planing processes are completed successively, which effectively ensures the flatness of the datum, maximizes the utilization of material value, and ensures the smooth feeding of the back processing.

Equipped with two front and bottom planing cutters, the rough planing and fine planing processes are completed successively, which effectively ensures the flatness of the datum, maximizes the utilization of material value, and ensures the smooth feeding of the back processing.

Feeding double active lower wheel, the cylinder provides idler pressure, wet and dry materials can be fed smoothly. The worktable processing technology treated with special materials greatly improves the wear resistance of the worktable.

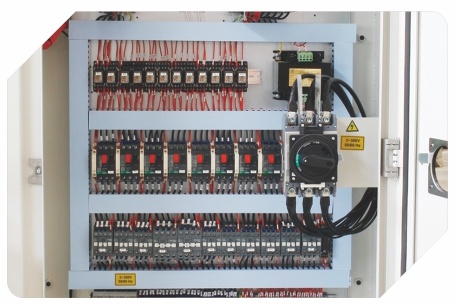

The reducer based on high-speed operation is connected to a powerful universal shaft and is equipped with a frequency conversion + permanent magnet motor feeding system. And equipped with international brand electrical components, strong stability.

Machine specification

| Model | VH-M616A | |

| Machine parameters | Working width(mm) | 25~180 |

| Working thickness(mm) | 8~120 | |

| In-feed-table length(mm) | 1500 | |

| Feeding speed(m/min) | 15~100 | |

| Spindle diameter(mm) | φ40 | |

| left and right spindle revolution speed(r/min) | 8000 | |

| 1st up and bottom spindles | 7000 | |

| 2st up and bottom spindles | 8000 | |

| Air pressure(Mpa) | 0.6 | |

| Motor power(kw) | 1st Bottom spindle | 7.5kw/10HP |

| 2nd Bottom spindle | 7.5kw/10HP | |

| Right vertical spindle | 7.5kw/10HP | |

| Left vertical spindle | 11kw/15HP | |

| 1st Top spindle | 11kw/15HP | |

| 2nd Top spindle | 7.5kw/10HP | |

| Top spindle lifting | 0.37kw/0.5HP | |

| Feeding beam lifting | 1.1kw/1.5HP | |

| Feeding motor | 66.7kw/9HP | |

| side of clamping | 2.2kw/3HP | |

| Total power | 31.55kw/40.8HP | |

| Spindle diameter(mm) | 1st Bottom spindle | φ125~φ140 |

| 2nd Bottom spindle | φ125~φ140 | |

| Right vertical spindle | φ125~φ160 | |

| Left vertical spindle | φ125~φ160 | |

| 1st Top spindle | φ125~φ160 | |

| 2nd Top spindle | φ125~φ160 | |

| Remar | Top spindle lifting | φ140 |

| Dust outlet diameter(mm) | φ140 | |

| Overall dimensions(mm) | L4780*W1700*H1900 | |

| Weight(kg) | 5300 | |

| Air volume | / |

Machine structure

The internal structure is precise and orderly

Concise operation panel

Front double lower idler with cylinder floating

Flanged disc type heavy universal shaft

Front double underplaning tool shaft

Encryption belt cylinder side top

Copyright © 2020 V-hold Woodworking Machinery Manufacturing Co., Ltd. | All Rights Reserved Sitemap