V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

VH-MB2032

| SPECIFICATION AND MODEL | MB2032 |

| Max. working width (mm) | 320 |

| Max. working thickness (mm) | 120 |

| Min. working thickness(mm) | 15 |

| Min. working length (mm) | 320 |

| Cutter knife | 4 |

| Flat knife spec | 320*30*6 |

| Spindle rotation rate | 5000 |

| Feeding speed | 5~16 |

| Spindle dia | Φ 110 |

| Top spindle power | 5.5 |

| Bottom spindle power | 4 |

| Feeding motor power | 1.5 |

| Elevating motor power | 0.37 |

| Total power | 11.37 |

| Dimension | 1880*780*1650 |

| SPECIFICATION AND MODEL | MB2063 | MB2045D | MB2040 | MB2032 |

| Max. working width (mm) | 635 | 450 | 405 | 320 |

| Max. working thickness (mm) | 200 | 150 | 170 | 120 |

| Min. working thickness (mm) | 15 | 15 | 15 | 15 |

| Min. working length (mm) | 320 | 320 | 320 | 320 |

| Cutter knife | 4 | 4 | 4 | 4 |

| Flat knife spec | 635*30*6 | 450*30*6 | 405*30*6 | 320*30*6 |

| Spindle rotation rate | 5000 | 4500 | 5000 | 5000 |

| Feeding speed | 5~20 | 5~16 | 5~16 | 5~16 |

| Spindle dia | Φ 110 | Φ 110 | Φ 110 | Φ 110 |

| Top spindle power | 11 | 7.5 | 7.5 | 5.5 |

| Bottom spindle power | 7.5 | 5.5 | 5.5 | 4 |

| Feeding motor power | 2.2 | 2.2 | 1.5 | 1.5 |

| Elevating motor power | 0.37 | 0.37 | 0.37 | 0.37 |

| Total power | 21.07 | 15.57 | 14.87 | 11.37 |

| Dimension | 2700*1268*1680 | 2280*1260*1680 | 2220*950*1650 | 1880*780*1650 |

Working width 320mm

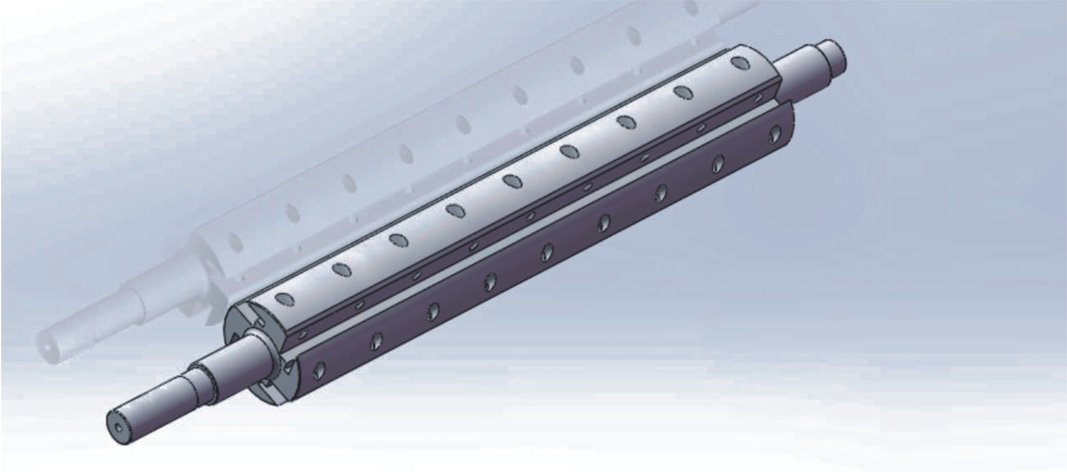

Attached flat knife shaft

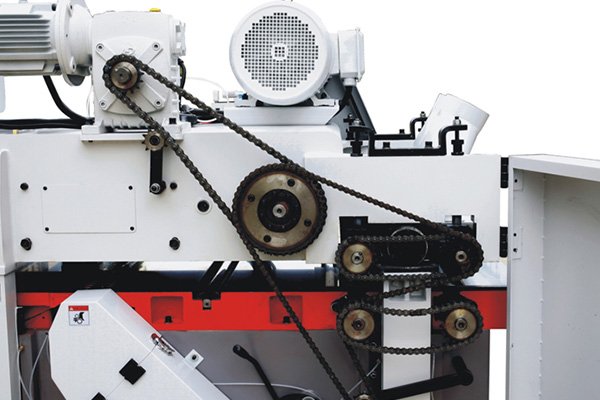

Feeding Frequency

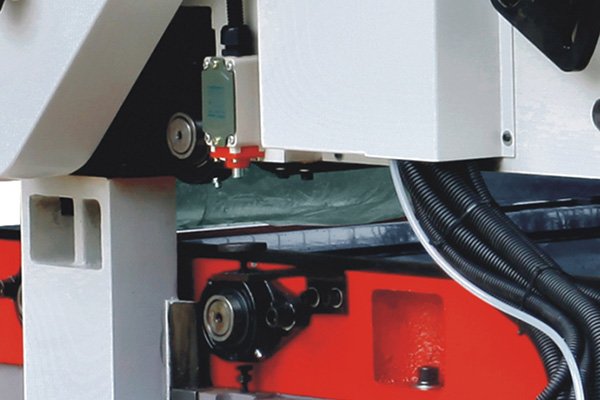

The configuration set to the cent ralized lubrication system, facilitate the lifting system maintenance lubrication.

Digital display, easy operation, energy saving,reduction of mechanical transmission wear.

Simply preset thickness timber placed at the microswitch, you can do simple thickness settings.

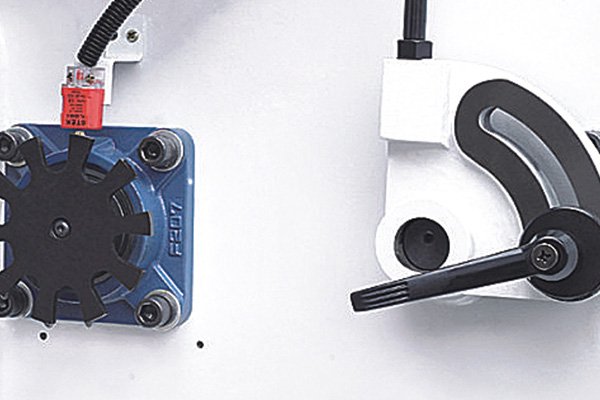

The thickness of the display gate magnetic sensors,accuracy is much higher than conventional proximity sensor.

Machine emergency stop or abnormal reactions only feed stop and start.

Feeding device is with clutch, which can prevent overload and give a safe operation.

Auto grease device keeps the machine always lubricated during working.

Alarm detector: When overload or stripping occurs with feeding chain, the alarm switch will give out signal alarm.

The product is provided with imported digital display device,which can be operated directly to processing thickness from operating panel with the accuracy up to 0.05mm; besides,upper and lower planning motor is provided with current meter for visual observing if it is overloaded while working.

3. Standard Configuration Option

MB2032: Blade size(320X30X6MM)X8PCS

Arbor screw precision machining

Provide fine planing surfacing, and no noise

Arbor screw assembly removable tungsten carbide blade

MB2032: Blade size (30×12×1.5)×45pcs

Copyright © 2020 V-hold Woodworking Machinery Manufacturing Co., Ltd. | All Rights Reserved Sitemap