Company Advantages1. double sided planer The materials are carefully selected and thick, and the advanced printing process is adopted. The patterns are clear and the colors are bright, and it is not easy to fade or fade after long-term use.

2. Because of the product emits little infrared light, it is highly suitable for goods and materials that are sensitive to heat. V-hold Machinery is a leading woodworking machinery manufacturer & supplier since 1996, main products include 4-sided moulder &

multiple rip saw3. This product is not susceptible to temperature variations. The ingredients contained would stay lazy when the temperature changes. V-hold Machinery has over 27 years of professional four-sided plane production & wood board production

4. Unlike the traditional bulbs, the product is supplied with a low voltage to ensure users' safety. Thus, the inductance is developed as small as possible to ensure high peak current which produces enough brightness.

5. Containing no heavy metals such as lead, cadmium, and mercury that can not biodegrade, it causes no pollution to the land and water.

VH-MB2045D

| SPECIFICATION AND MODEL | MB2045D |

| Max. working width (mm) | 450 |

| Max. working thickness (mm) | 150 |

| Min. working thickness (mm) | 15 |

| Min. working length (mm) | 320 |

| Cutter knife | 4 |

| Flat knife spec | 450*30*6 |

| Spindle rotation rate | 4500 |

| Feeding speed | 5~16 |

| Spindle dia | Φ 110 |

| Top spindle power | 7.5 |

| Bottom spindle power | 5.5 |

| Feeding motor power | 2.2 |

| Elevating motor power | 0.37 |

| Total power | 15.57 |

| Dimension | 2280*1260*1680 |

| SPECIFICATION AND MODEL | MB2063 | MB2045D | MB2040 | MB2032 |

| Max. working width (mm) | 635 | 450 | 405 | 320 |

| Max. working thickness (mm) | 200 | 150 | 170 | 120 |

| Min. working thickness (mm) | 15 | 15 | 15 | 15 |

| Min. working length (mm) | 320 | 320 | 320 | 320 |

| Cutter knife | 4 | 4 | 4 | 4 |

| Flat knife spec | 635*30*6 | 450*30*6 | 405*30*6 | 320*30*6 |

| Spindle rotation rate | 5000 | 4500 | 5000 | 5000 |

| Feeding speed | 5~20 | 5~16 | 5~16 | 5~16 |

| Spindle dia | Φ 110 | Φ 110 | Φ 110 | Φ 110 |

| Top spindle power | 11 | 7.5 | 7.5 | 5.5 |

| Bottom spindle power | 7.5 | 5.5 | 5.5 | 4 |

| Feeding motor power | 2.2 | 2.2 | 1.5 | 1.5 |

| Elevating motor power | 0.37 | 0.37 | 0.37 | 0.37 |

| Total power | 21.07 | 15.57 | 14.87 | 11.37 |

| Dimension | 2700*1268*1680 | 2280*1260*1680 | 2220*950*1650 | 1880*780*1650 |

VH-MB2045D

Working width 450mm

Attached flat knife shaft

Feeding Frequency

After driving roller workbench configuration

Centralized lubrication system

Centralized lubrication systemThe configuration set to the cent ralized lubrication system, facilitate the lifting system maintenance lubrication.

Feeding frequency inverter

Feeding frequency inverterDigital display, easy operation, energy saving,reduction of mechanical transmission wear.

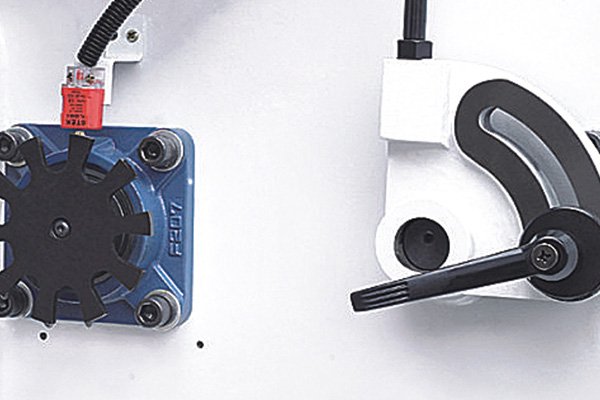

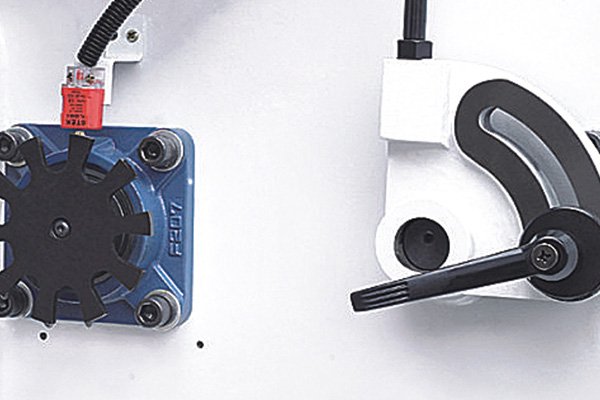

Thickness Quick set

Thickness Quick setSimply preset thickness timber placed at the microswitch, you can do simple thickness settings.

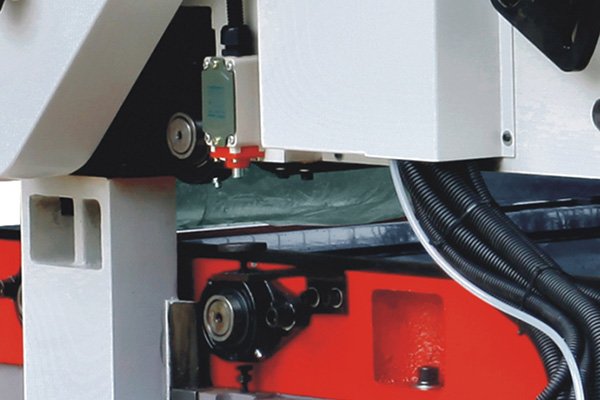

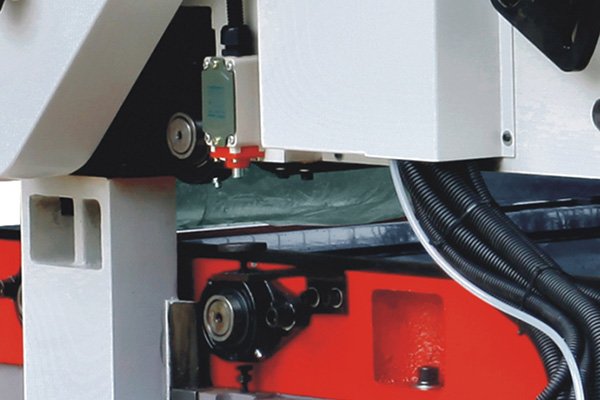

Gate magnetic induction switch

Gate magnetic induction switchThe thickness of the display gate magnetic sensors,accuracy is much higher than conventional proximity sensor.

Rear operation box

Rear operation boxMachine emergency stop or abnormal reactions only feed stop and start.

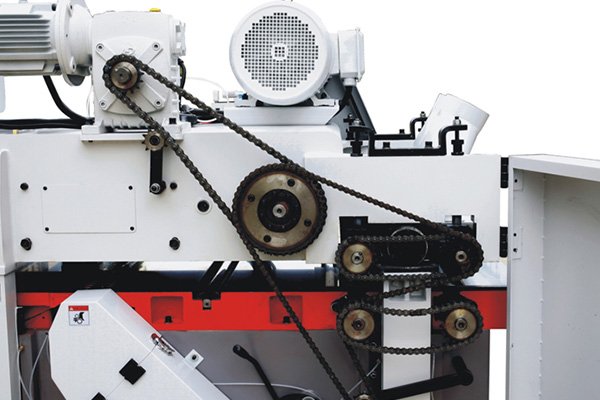

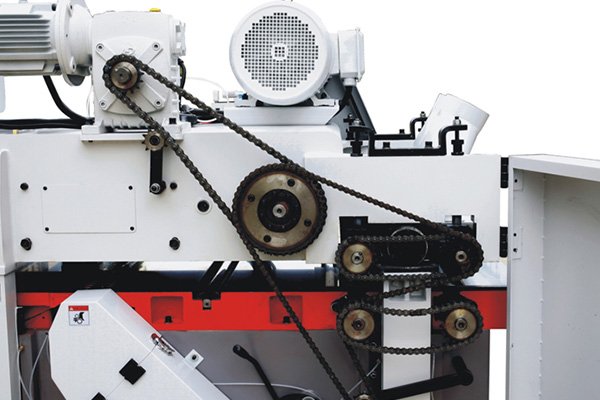

Feeding device is with clutch, which can prevent overload and give a safe operation.

Auto grease device keeps the machine always lubricated during working.

Alarm detector: When overload or stripping occurs with feeding chain, the alarm switch will give out signal alarm.

The product is provided with imported digital display device,which can be operated directly to processing thickness from operating panel with the accuracy up to 0.05mm; besides,upper and lower planning motor is provided with current meter for visual observing if it is overloaded while working.

3. Standard Configuration Option

Flat knife blade

MB2045D:Blade size(450X30X6MM)X8PCS

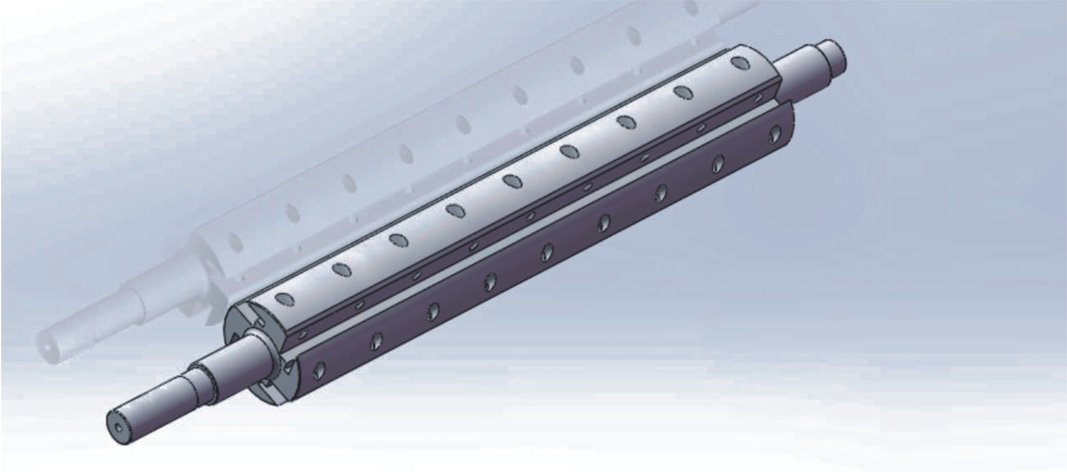

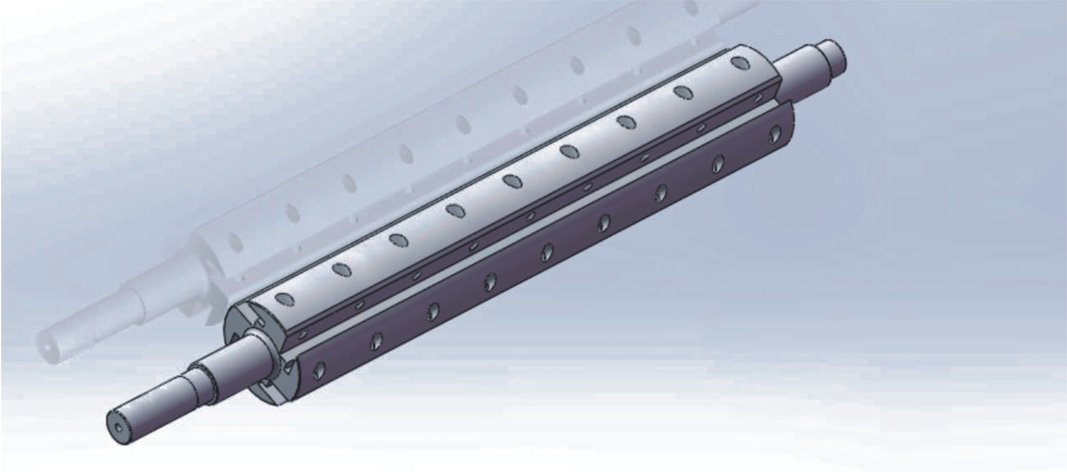

Screw arbor (Heavy Duty)

Arbor screw precision machining

Provide fine planing surfacing, and no noise

Arbor screw assembly removable tungsten carbide blade

MB2045:Blade size (30×12×1.5)×63pcs

Company Features1. We have a professional production team who are supported by internal and external resources. Frequent internal training is held to improve workers' skills, and cutting-edge manufacturing technologies are introduced to support their work.

2. V-hold Woodworking Machinery Manufacturing Co., Ltd will seize the opportunity to continue the rapid and healthy development of itself in double sided planer industry. Inquire!