V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

VH-MB2040

| SPECIFICATION AND MODEL | MB2040 |

| Max. working width (mm) | 405 |

| Max. working thickness (mm) | 170 |

| >Min. working thickness (mm) | 15 |

| Min. working length (mm) | 320 |

| Cutter knife | 4 |

| Flat knife spec | 405*30*6 |

| Spindle rotation rate | 5000 |

| Feeding speed | 5~16 |

| Spindle dia | Φ 110 |

| Top spindle power | 7.5 |

| Bottom spindle power | 5.5 |

| Feeding motor power | 1.5 |

| Elevating motor power | 0.37 |

| Total power | 14.87 |

| Dimension | >2220*950*1650 |

| SPECIFICATION AND MODEL | MB2063 | MB2045D | MB2040 | MB2032 |

| Max. working width (mm) | 635 | 450 | 405 | 320 |

| Max. working thickness (mm) | 200 | 150 | 170 | 120 |

| Min. working thickness (mm) | 15 | 15 | 15 | 15 |

| Min. working length (mm) | 320 | 320 | 320 | 320 |

| Cutter knife | 4 | 4 | 4 | 4 |

| Flat knife spec | 635*30*6 | 450*30*6 | 405*30*6 | 320*30*6 |

| Spindle rotation rate | 5000 | 4500 | 5000 | 5000 |

| Feeding speed | 5~20 | 5~16 | 5~16 | 5~16 |

| Spindle dia | Φ 110 | Φ 110 | Φ 110 | Φ 110 |

| Top spindle power | 11 | 7.5 | 7.5 | 5.5 |

| Bottom spindle power | 7.5 | 5.5 | 5.5 | 4 |

| Feeding motor power | 2.2 | 2.2 | 1.5 | 1.5 |

| Elevating motor power | 0.37 | 0.37 | 0.37 | 0.37 |

| Total power | 21.07 | 15.57 | 14.87 | 11.37 |

| Dimension | 2700*1268*1680 | 2280*1260*1680 | 2220*950*1650 | 1880*780*1650 |

Working width 405mm (16 ")

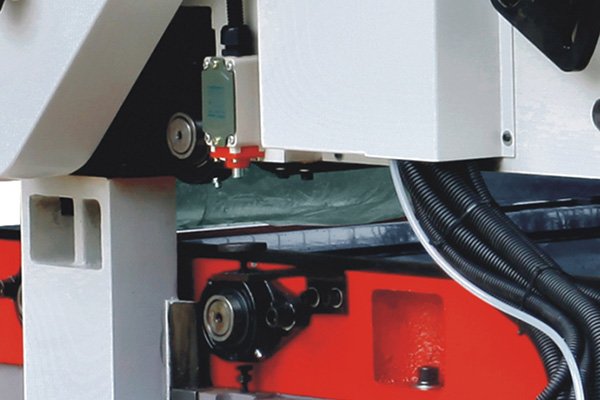

Attached flat knife shaft

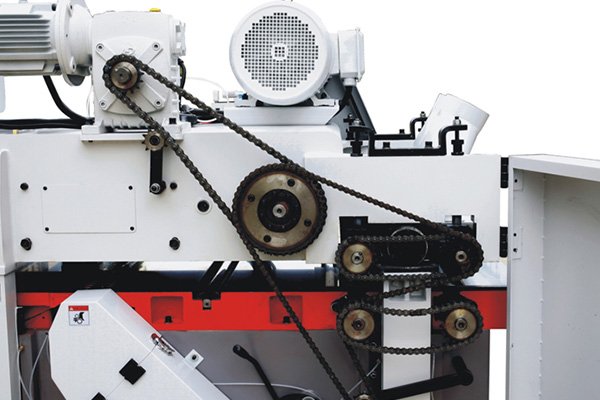

Feeding Frequency

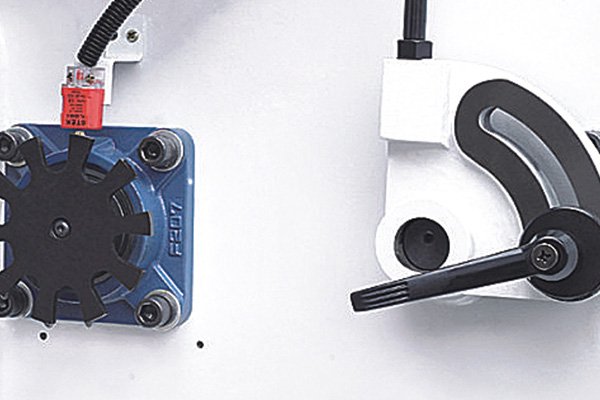

3. Standard Configuration Option

Flat knife blade

MB2040:Blade size(405X30X6MM)X8PCS

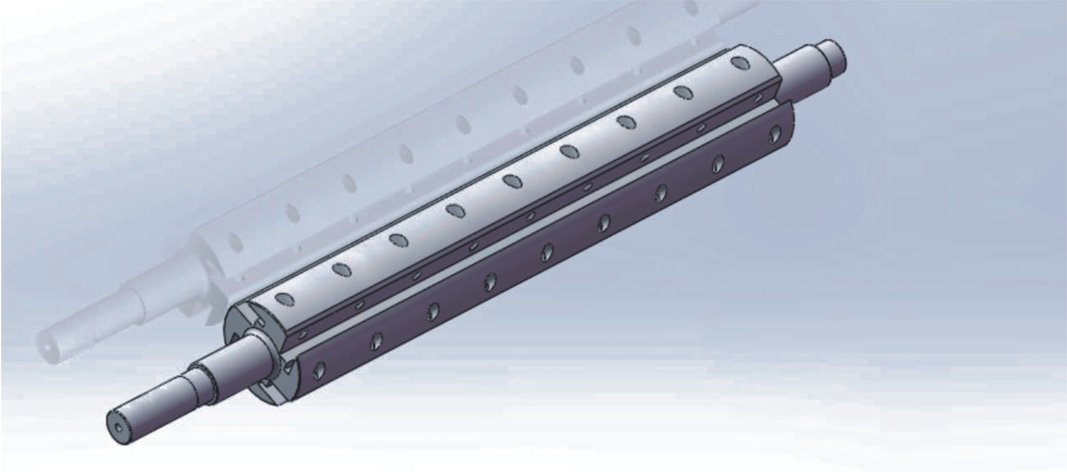

Screw arbor (Heavy Duty)

Arbor screw precision machining

Provide fine planing surfacing, and no noise

Arbor screw assembly removable tungsten carbide blade

MB2040: Blade size (30×12×1.5)×57pcs

Copyright © 2020 V-hold Woodworking Machinery Manufacturing Co., Ltd. | All Rights Reserved Sitemap