V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

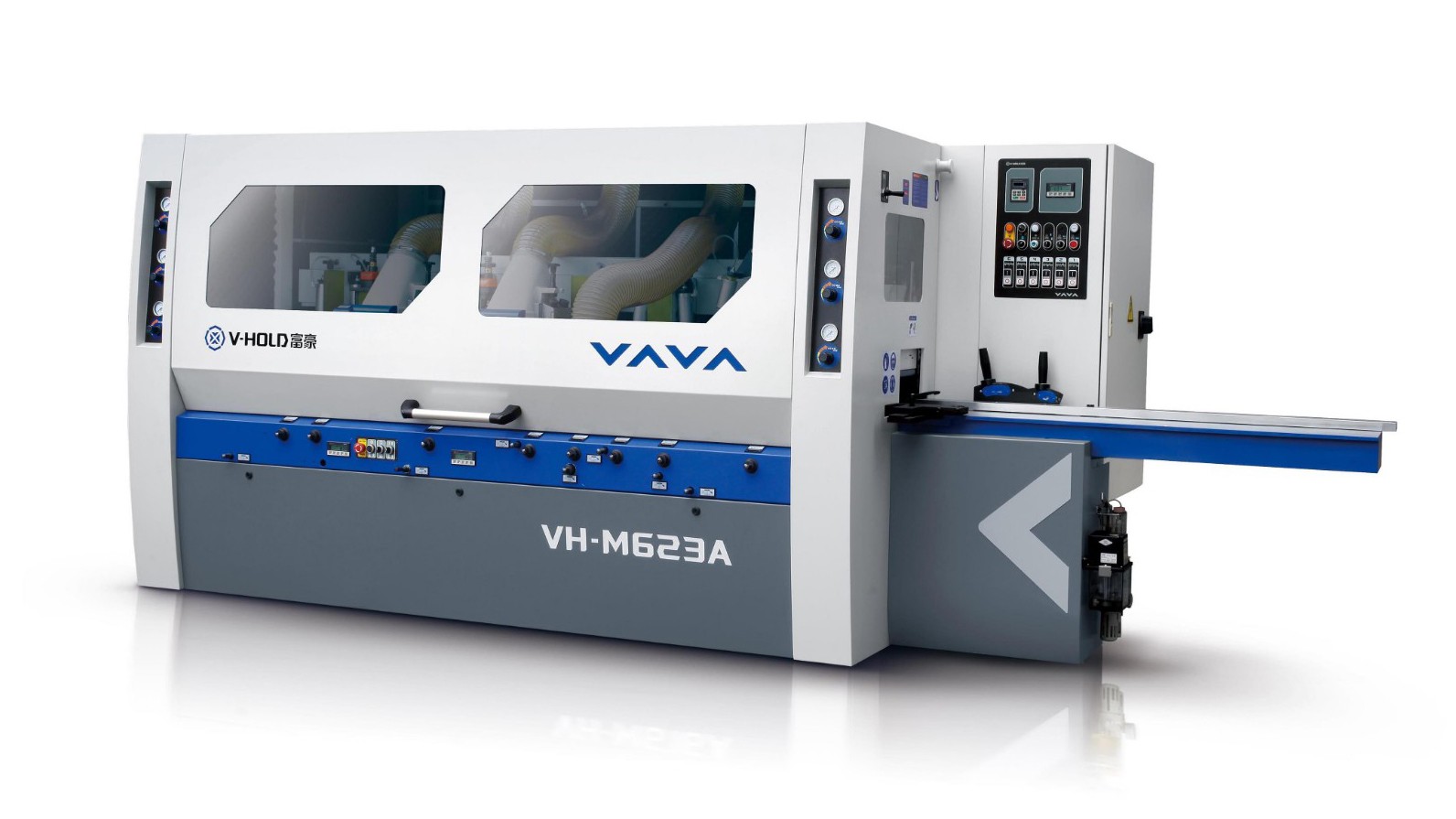

23A series four-sided planer is mainly used for hardwood lines, floors, wooden doors, door frames, window frames and other large cutting volume one-time four-sided molding processing.

Product features:

1. The full range of products are equipped with frequency conversion feeding system, feeding 6-36m / min.

2. Standard short material device.

3. High precision spindle, rotational speed 6200r/min (optional higher rotational speed).

4. Start the independent motor and open and close the spindle separately according to the customer's actual processing requirements (optional with different configuration motor power).

5. Heavy cutting gearbox.

6. Equipped with 3 positions emergency stop device, install open door cover power off and feed port limit high limit switch.

Wood sample of processed products

Machine function

|  |  |

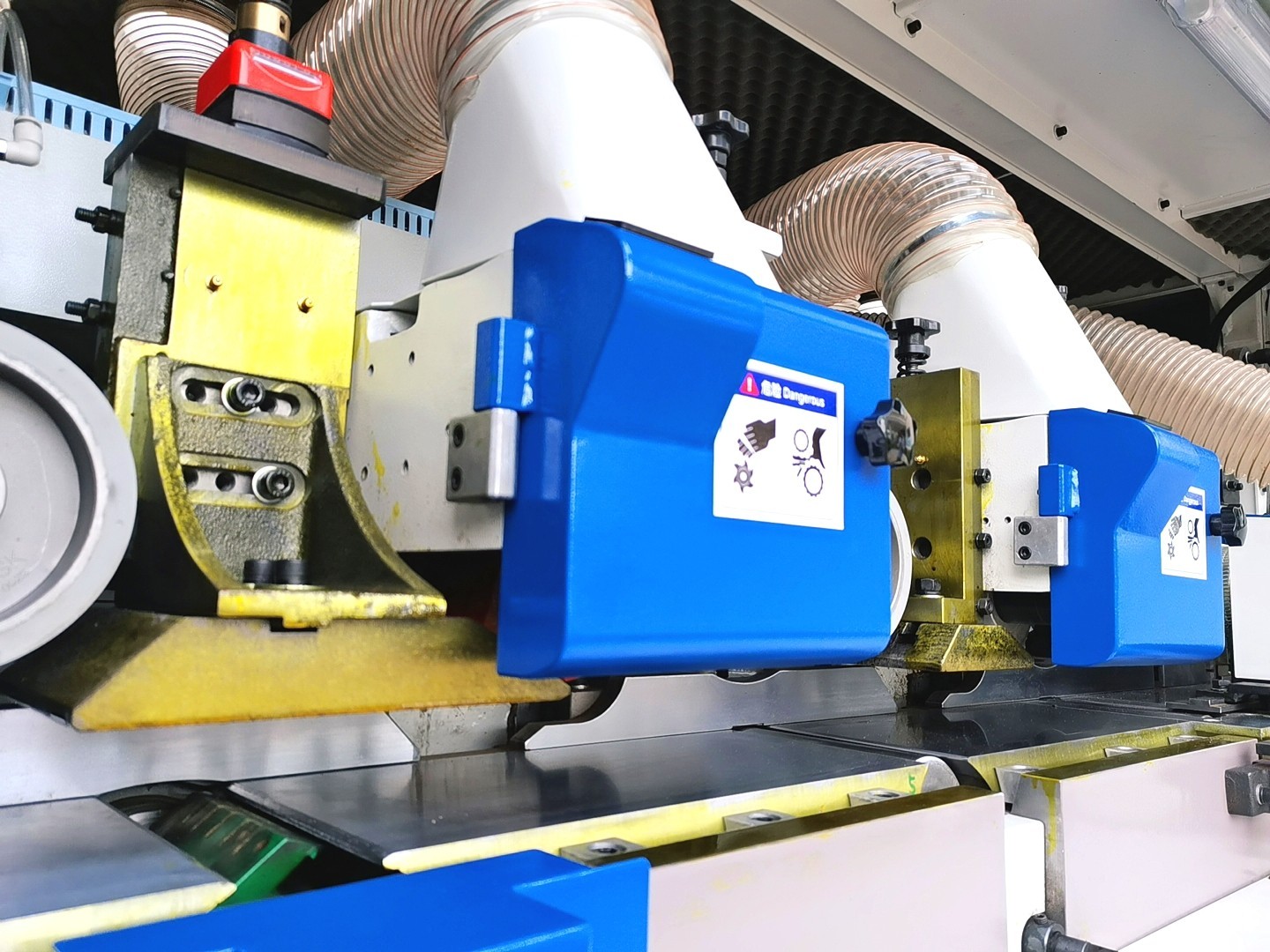

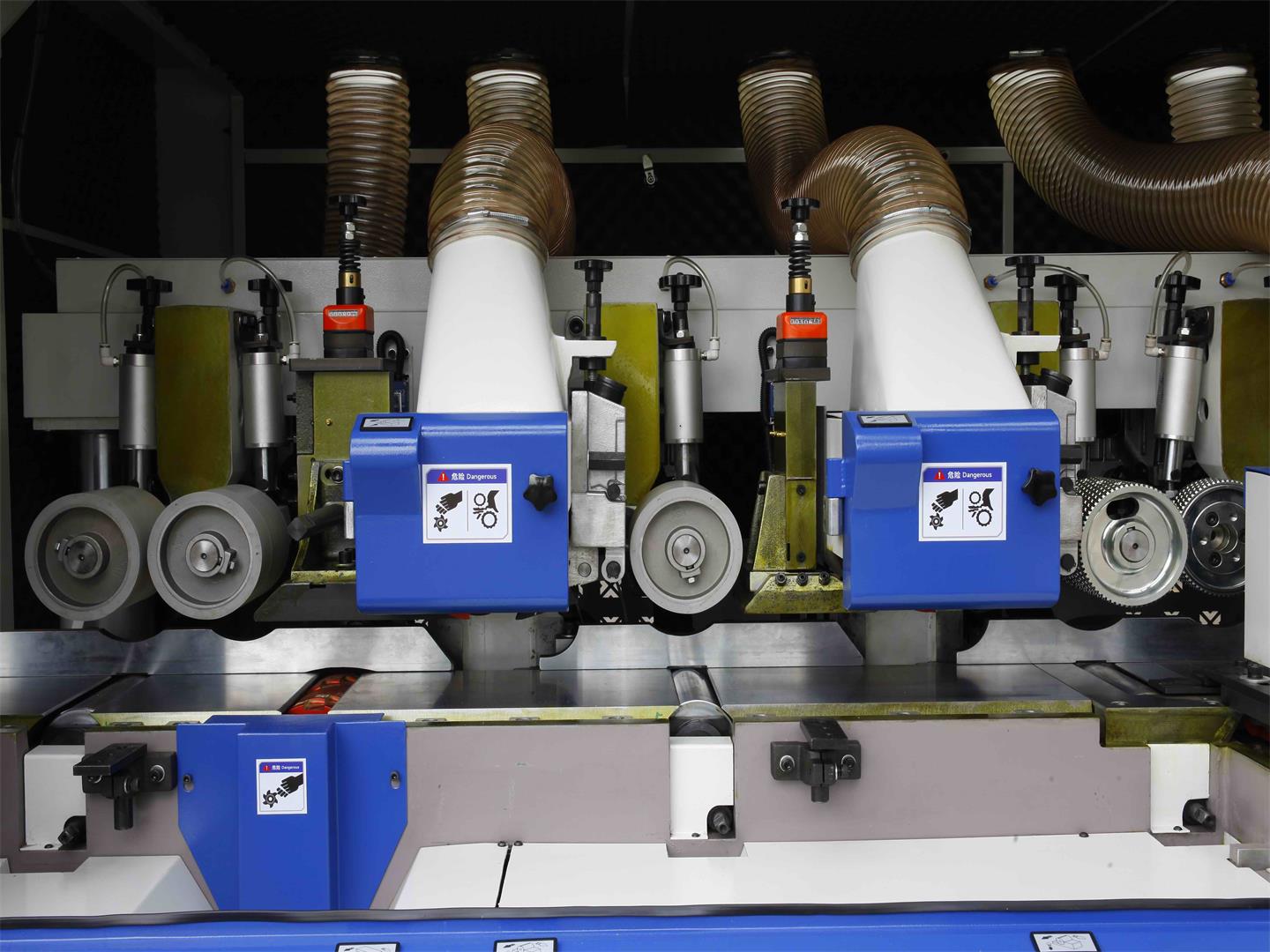

Quick liftable short material device This mechanism enables the smooth feeding for short woods.The auxiliary feeding roller has the function of transmission,which makes the feeding more briskly.With liftable feeding roller,you can change and adjust the knife easily. | Each cutter shaft is assembled and tested under air-conditioned enviroment and is supported by SKF bearing.The stable-worked shaft guarantees the surface smoothness of finished products. | Efficient dust removal,the new duct suction structure can more effectively remove wood chips.Minimizing dents on the surface of the finished product and effectively controlling noise. |

|  |  |

| There is feeder seitch and scram switch,easy to operate and adjust. | Feeding frequency inverter Digital display,easy to operate,energy saving,protect the machine from wearing because of mechanical transmission. | The feed port has an active feed supporting wheel,and the culinder provides top roller pressure,allowing for smooth feeding of both wet and dry materials. |

Machine specification

| Model | VH-M623A | |

| Machine parameters | Working width(mm) | 25~230 |

| Working thickness(mm) | 8~160 | |

| In-feed-table length(mm) | 1970 | |

| Feeding speed(m/min) | 6~36 | |

| Spindle diameter(mm) | φ40 | |

| Spindle revolution speed(r/min) | 6200 | |

| Air pressure(Mpa) | 0.6 | |

| Motor power(kw) | 1st Bottom spindle | 7.5kw/10HP |

| Right vertical spindle | 7.5kw/10HP | |

| Left vertical spindle | 7.5kw/10HP | |

| 1st Top spindle | 11kw/15HP | |

| 2nd Top spindle | 7.5kw/10HP | |

| 2nd Bottom spindle | 7.5kw/10HP | |

| Top spindle lifting | 0.37kw/0.5HP | |

| Feeding beam lifting | 0.75kw/1HP | |

| Feeding motor | 5.5kw/7.5HP | |

| Total power | 55.12kw/75HP | |

| Spindle diameter(mm) | 1st Bottom spindle | φ125 |

| Right vertical spindle | φ125~φ180 | |

| Left vertical spindle | φ125~φ180 | |

| 1st Top spindle | φ125~φ180 | |

| 2nd Top spindle | φ125~φ180 | |

| 2nd Bottom spindle | φ125~φ200 | |

| Remar | Feeding wheel diamter(mm) | φ140 |

| Dust outlet diameter(mm) | φ140 | |

| Overall dimensions(mm) | L4400*W1750*H1940 | |

| Weight(kg) | 4400 | |

| Air volume | 12800m³/h |

Machine structure

|  |  |

| The internal structure is precise and orderly. | Concise operation panel | Rise and fall of cylindrical column |

|  |  |

| Weight-resistant cutting gearbox | Structure upgrade of front and rear press plate | Thickening panel, ruler |

Copyright © 2020 V-hold Woodworking Machinery Manufacturing Co., Ltd. | All Rights Reserved Sitemap