Company Advantages1. During the foot outline extraction stage of V-hold Machinery tenoner machine , the high-efficient, all-round, and customized CAD (computer-aided design) and CAM (computer-aided manufacturing) technology are used to guarantee the precision. V-hold Machinery has over 27 years of professional four-sided plane production & wood board production

2. The design and realization of the V-hold Machinery tenoner machine is based on grooving machine for wood . V-hold Machinery is a leading woodworking machinery manufacturer & supplier since 1996, main products include 4-sided moulder &

multiple rip saw3. [企业简称] As a professional sheet metal processing enterprise, we can undertake tenoner machine processing and customization of various shapes and structures, and the processed products are strong and hard, resistant to falling and wear, anti-corrosion, moisture-proof, rust-proof and other performances, long-lasting Use without deformation.

4. [企业简称] actively learns advanced foreign manufacturing experience and production technology. The tenoner machine produced is excellent in workmanship, reliable in performance, stable in quality, and has passed the strict quality inspection of the national authoritative quality inspection agency.

5. tenoner machine It is safe, highly entertaining, highly irritating, easy to operate, and easy to maintain. It is widely used in public places such as residential quarters, playgrounds, large shopping malls, and kindergartens.

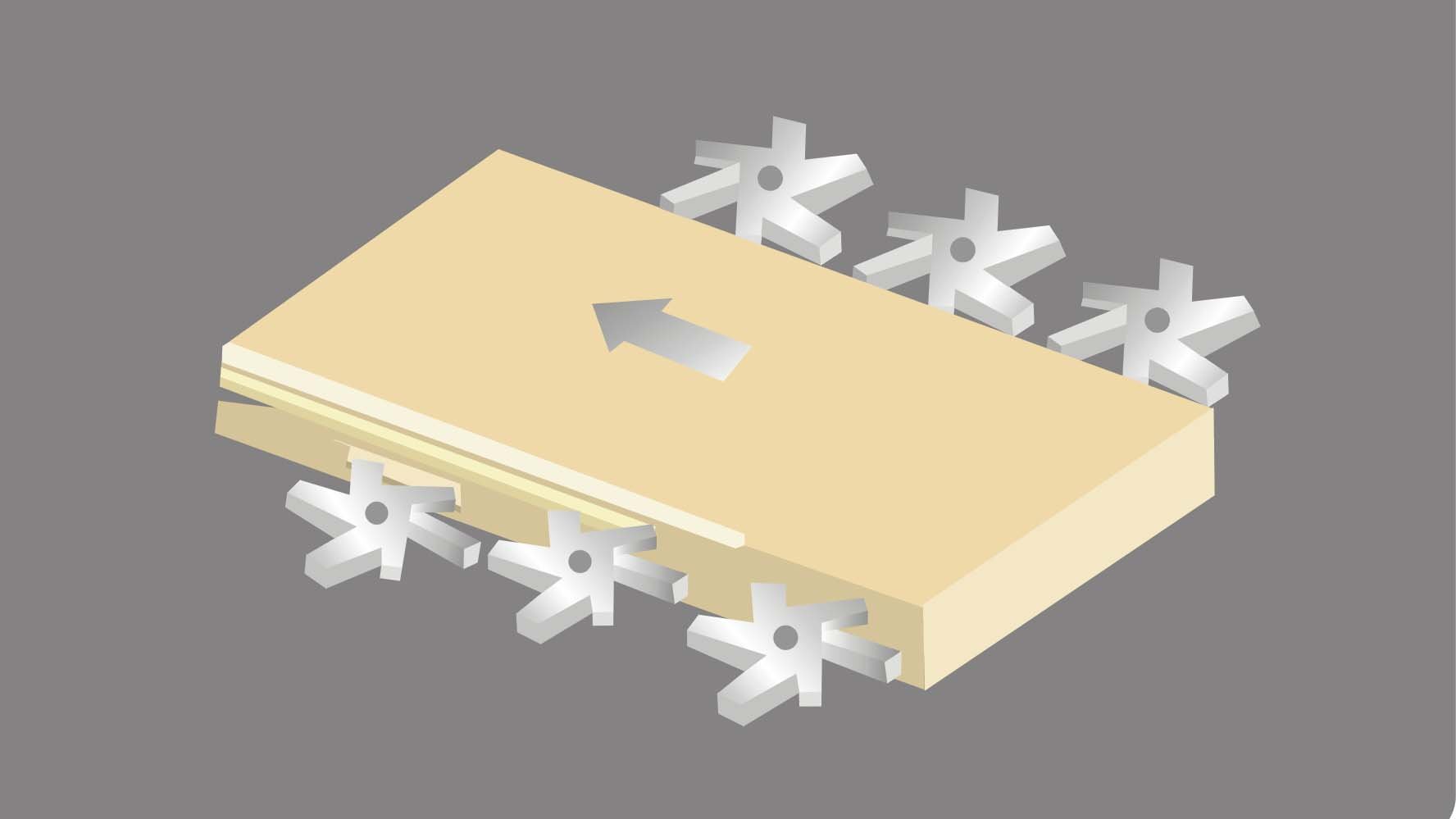

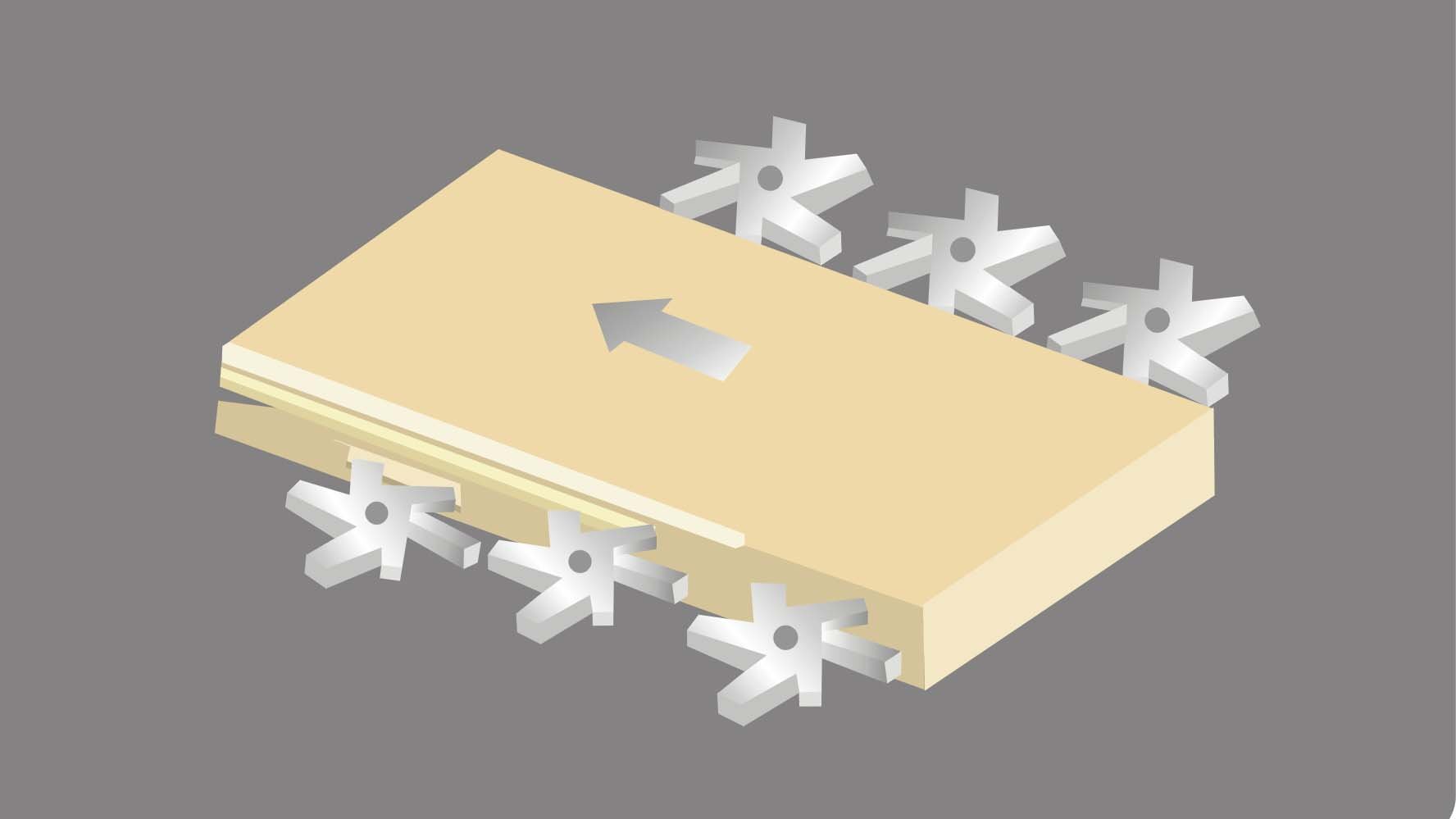

The floor plates are sent into the runnig bearings of the machining track with the material feeder and delivery rubber rollers, and the guide rails are made with extra hard materials, ensuring the machining precision.

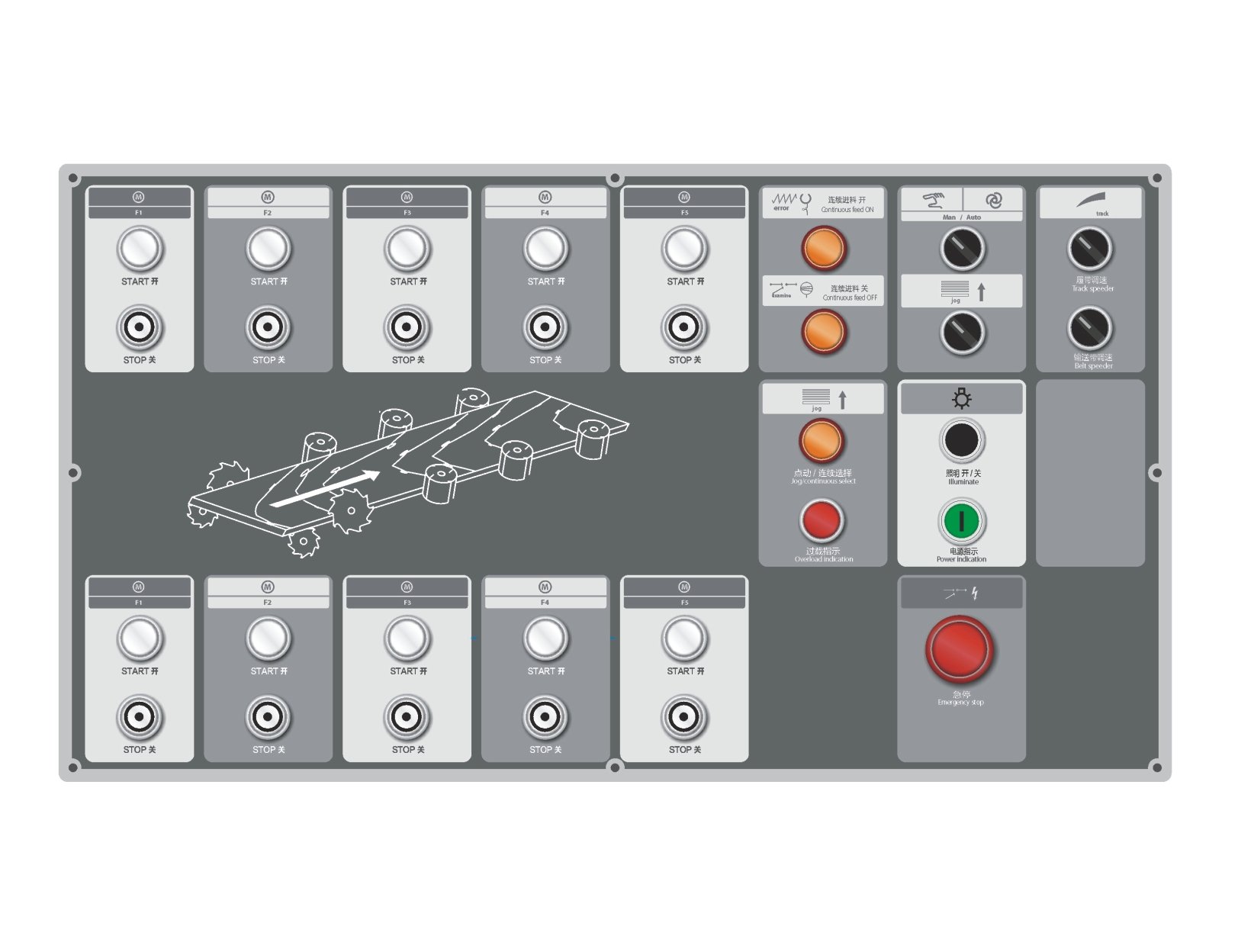

With the imported PLC and the frequency conversion device, the double-end miller works very smooth.

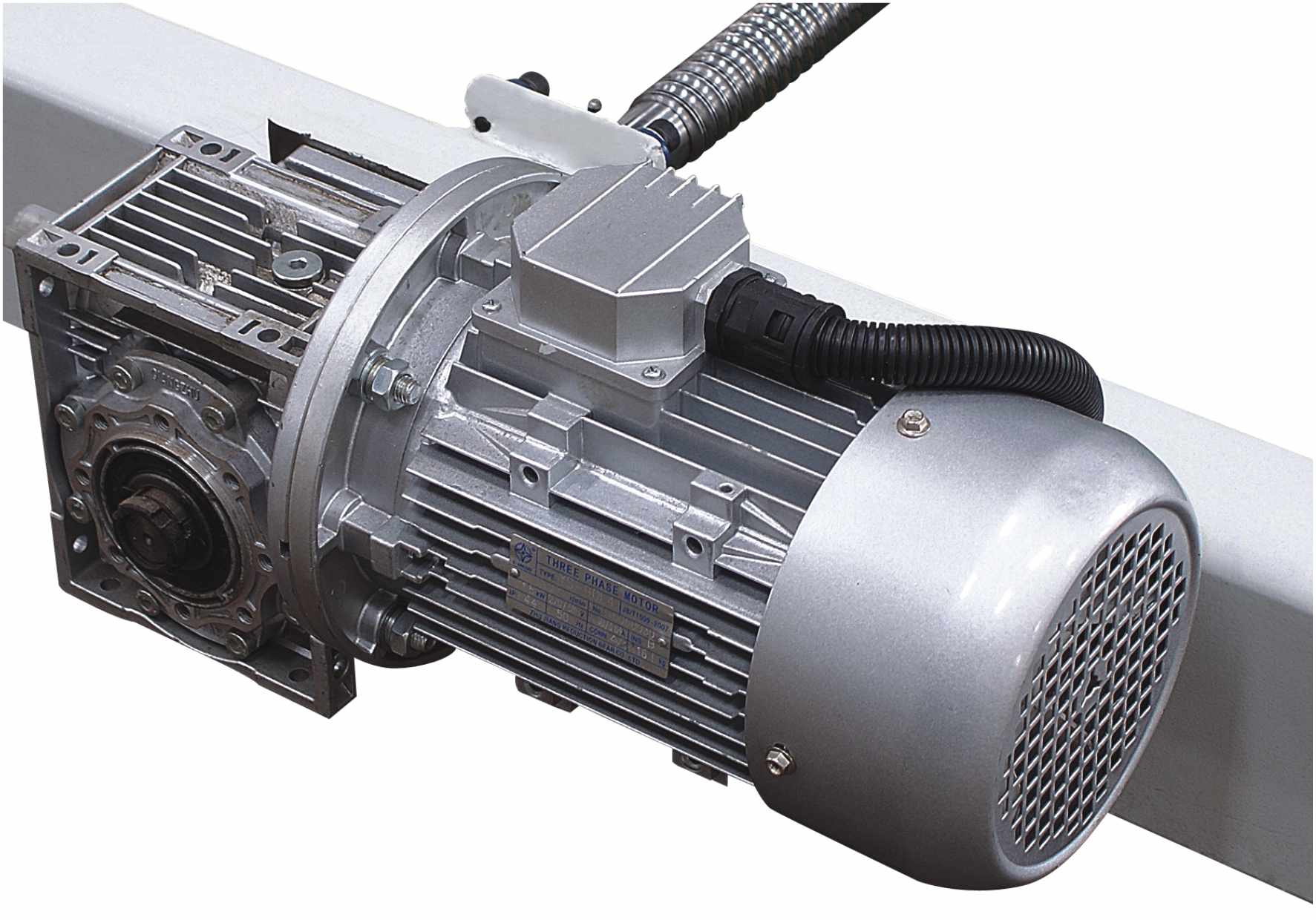

Forcefully feeding decelerator features speed regulation by frequency inverter.

With the built-in cleaning brush wheel, the dust inside the track guide rail can be cleaned automatocally.

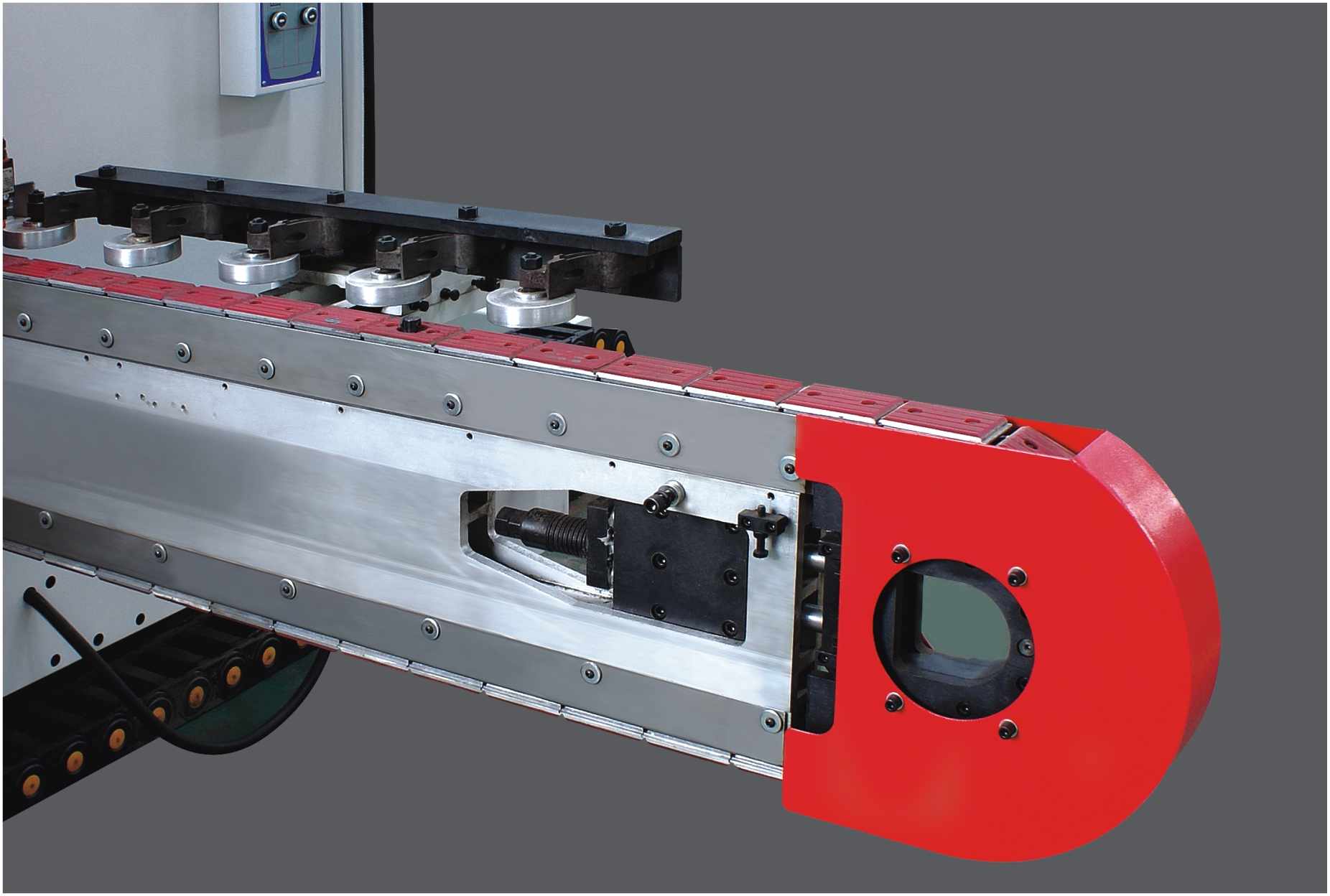

With the compact sawing shaft mechanism, the cutters are closed to the pressing belt, ensuring the machining stability.

Structure acting as ball-screw makes machine have more accurate adjustment.

| Specification and Model | MB2626D |

| Feeding speed (m/min) | 6-30m/min |

| Max. Working wiidth (mm) | 800mm |

| Min. Working width (mm) | 100mm |

| Max. Working length (mm) | 2600mm |

| Min. Working length (mm) | 300mm |

| Max. Working thickness (mm) | 60mm |

| Max. Working thickness (mm) | 10mm |

| Vertical and click shaft revolution (r/min) | 6000/6000-8000r/min |

| Vertical and click shaft diameter (mm) | Φ40mm |

| Vertical milling cutter diameter (mm) | Φ160-200mm |

| Click milling cutter diameter (mm) | Φ180mm |

| Feeding rubber roller diameter (mm) |

|

| Vertical spindle motor power (kw) | 3kwx6sets |

| Card buckle spindle motor power (kw) | 2.2kwx2sets |

| Feeding motor power (kw) | 3kw |

| Elevatory motor power (kw) | 0.75kw |

| Lifting motor power (kw) | 0.75kw (width openning motor) |

| Total power (kw) | 26.9kw |

| Air pressure (MPa) | 0.6MPa |

| Physcial dimension (mm) | 3450x2600x1670mm |

The main electrial components are import and famous

The floor plates are sent into the running bearings of the manchining track with material feeder and delivery rubber rollers, and the guide rails are made with extra hard materials ensuring the machining precis

Ajusting width by high precision ball screw

Company Features1. V-hold Woodworking Machinery Manufacturing Co., Ltd is a experienced tenoner machine manufacturer with a strong company culture. All our

double end tenoner for sale have conducted strict tests.

2. We adopt world-advanced technology when manufacturing tenoner for sale .

3. V-hold Woodworking Machinery Manufacturing Co., Ltd has successfully got several patents for technology. Continuously expanding the development connotation of grooving machine for wood industry is impending for V-hold Machinery. Please contact us!