V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

| Model | VH-M823 | |

| specification | Working width | 25-230 |

| Working thickness | 8-160 | |

| Working table length | 1970 | |

| Feeding speed | 6-36 | |

| Main spindle diameter | Φ 40 | |

| Main spindle revolution | 6500 | |

| Air pressure | 0.6 | |

| Motor power | 1st Lower shaft | 7.5kw/10H |

| 1st Right vertical spindle | 7.5kw/10HP | |

| 1st Left vertical spindle | 7.5kw/7.5HP | |

| 2nd Right vertical spindle | 7.5kw/10HP | |

| 2nd Left vertical spindle | 7.5kw/10HP | |

| 1st Upper shaft | 11kw/15HP | |

| 2nd Upper shaft | 7.5kw/10HP | |

| 2st Lower shaft | 7.5kw/10HP | |

| Feeding beam lifting | 1.1kw/1.5HP | |

| Feeding motor | 7.5kw/10HP | |

| Top power | 72.1kw/98HP | |

| Cutter diameter | 1st Lower shaft | Φ 125 |

| Right vertical spindle | Φ 125-Φ 180 | |

| Left vertical spindle | Φ 125-Φ 180 | |

| 1st Upper shaft | Φ 125-Φ 180 | |

| 2nd Upper shaft | Φ 125-Φ 180 | |

| 2nd Lower shaft | Φ 125-Φ 200 | |

| Remark | Feeding wheel diameter | Φ140 |

| Dust outlet diameter | Φ140 |

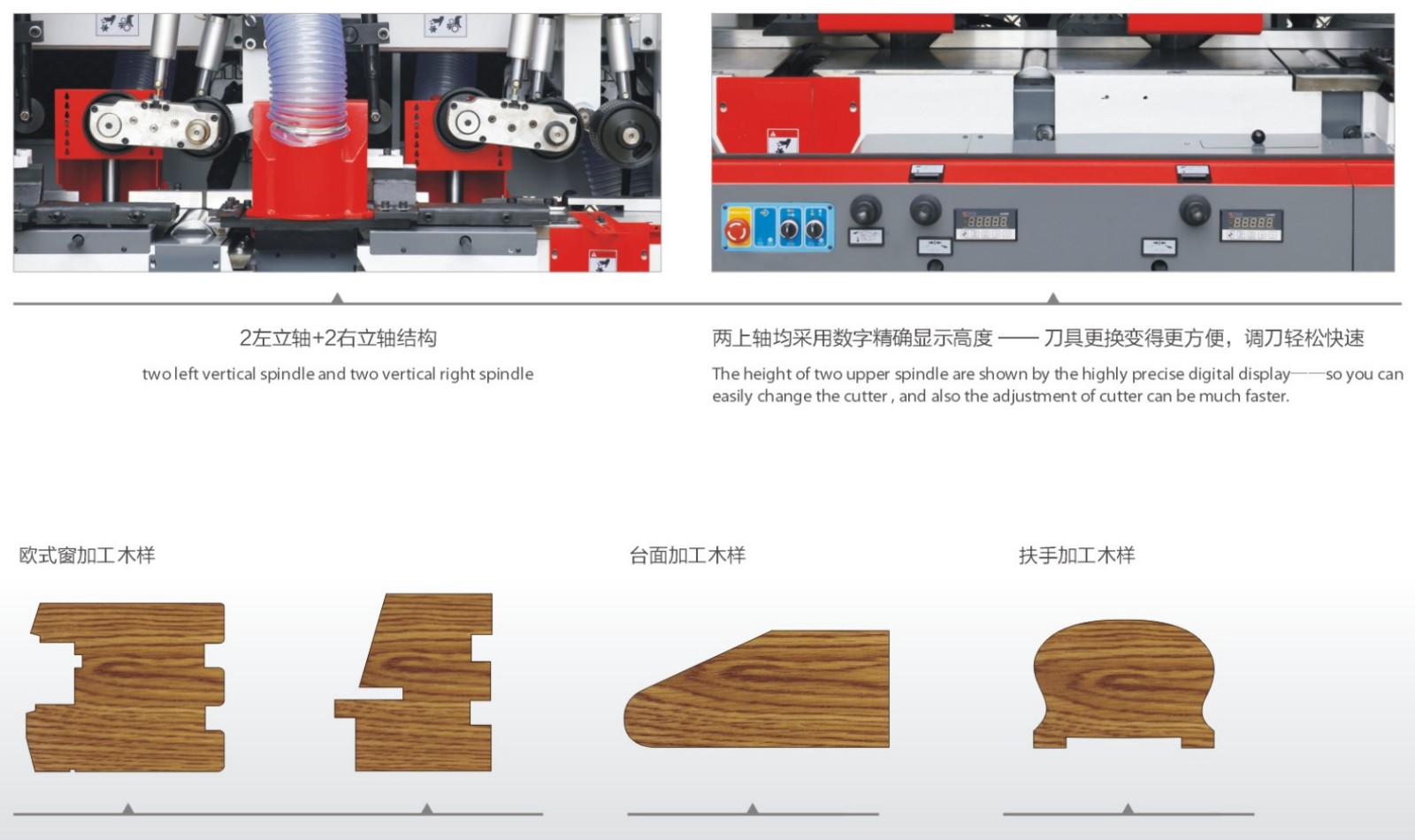

ELECTRONIC/PNEUMATIC/CONTROL CONFIGURATION

Feed frequency converter Frequency conversion digital display, feeding speed 6-36 m / min, easy to operate, reduce, energy saving, reduce mechanical variable speed wear. |

|

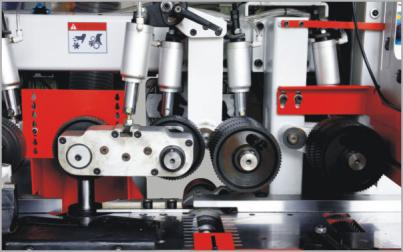

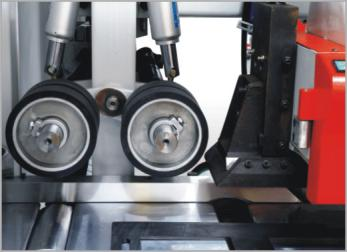

Fast hatch able short material This mechanism can effectively improve the smooth feeding of short material, and the auxiliary feeding wheel has the function of transmission, which makes the feeding more light, and the feeding wheel can be lifted to facilitate the replacement or adjustment of tool |  |

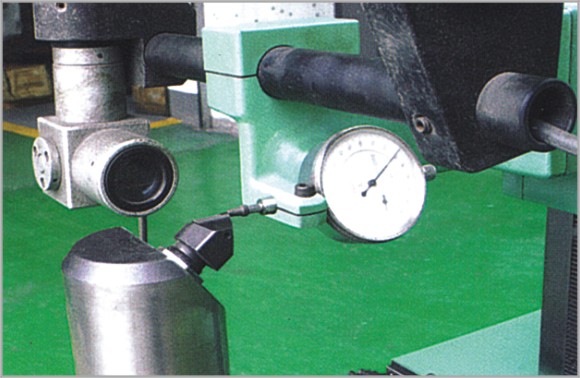

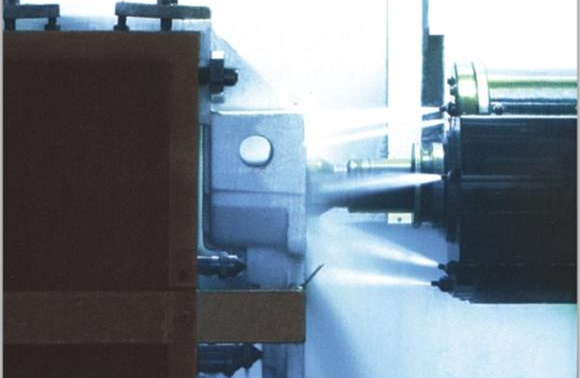

Precision spindle-Each tool shaft is assembled and tested in the air conditioning room. Both ends are supported by imported SKF bearings, absolutely smooth operation of the tool shaft, to ensure the surface finish of the finished product. |  |

Front and back press-The pressure can be adjusted separately, even if the thickness of wood changes greatly, it can be firmly pressed on the working table. |  |

| Heavy cutting gearbox. The feeding wheel is driven by universal joint and gearbox to ensure no power loss. The feeding is extremely smooth, the transmission force is strong, and the feeding precision is high. |  |

Post discharge active panel The rear lower shaft panel is free to move, and all kinds of tool replacement are very easy. |  |

The front and back pressing plate can be adjusted respectively. Even the wood thickness changes frequently, you can stabilize it under worktable. |  |

Excellent processing equipment Meticulous careful production to ensure that each part is almost perfect! |  |

Rear discharge activity panel. The rear lower axle panel can be moved freely, and all kinds of tools can be replaced easily. |  |

Processing technology

| Bed height rigid integrated structure It is made of cast iron with damping property to ensure the smooth operation of cutter shaft and feeding system.Sophisticated processing equipment |

|

Sophisticated processing equipment Meticulous and meticulous production to ensure that every part is nearly perfect! |  |

Japan four axis linkage machining center All shaft frame, gear box and other accessories, the company is equipped with its own processing center to work, to ensure that the accessories precision |  |

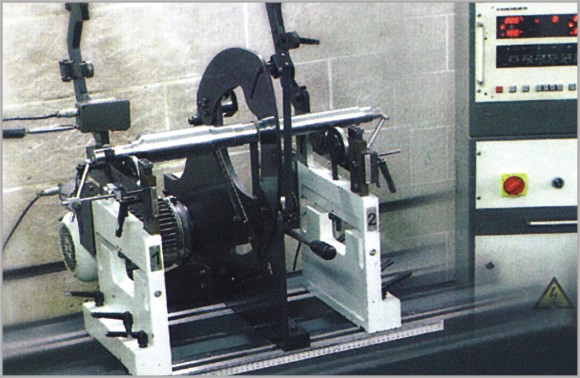

Spindle dynamic balance test Each spindle is equipped with imported SKF bearing to ensure the high precision and smooth operation of the cutter shaft Line. |  |

QUALIFICATION

|  |  |  |  |

Copyright © 2020 V-hold Woodworking Machinery Manufacturing Co., Ltd. | All Rights Reserved Sitemap