V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

VH-M626V four-sided planer is a kind of heavy-duty four-sided planer, which is applicable to the wood-ware which both sides need large cutting for American classical door and frame processing.

Product features:

1. Max working width 260mm and max working thickness 200mm.

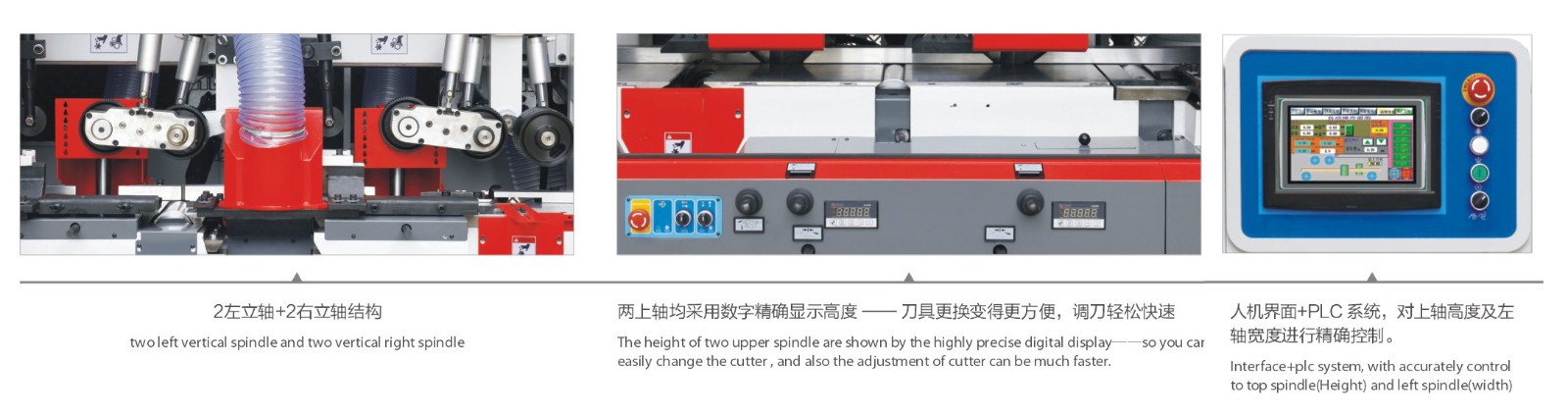

2. 2 left vertical spindles and 2 vertical right spindles.

3. The height of 2 upper spindle are shown by the highly precise digital display --so you can easily change the cutter,and also the adjustment of cutter cn be much faster.

4.Interfacce+plz system,with accurately control to top spindle(height) and left spindle(width).

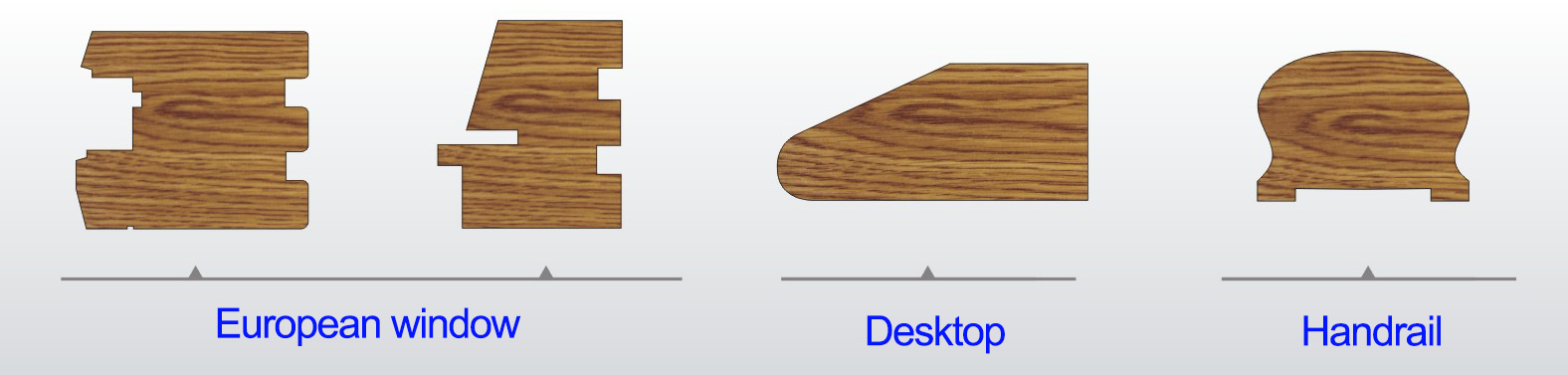

Wood sample of processed products

Machine function

Machine specification

| Model | VH-M626V | |

| Machine parameters | Working width(mm) | 25~260 |

| Working thickness(mm) | 10~200 | |

| In-feed-table length(mm) | 1970 | |

| Feeding speed(m/min) | 6~36 | |

| Spindle diameter(mm) | φ50 | |

| Spindle revolution speed(r/min) | 6500 | |

| Air pressure(Mpa) | 0.6 | |

| Motor power(kw) | 1st Bottom spindle | 7.5kw/10HP |

| Right vertical spindle | 11kw/15HP | |

| Left vertical spindle | 11kw/15HP | |

| 1st Top spindle | 11kw/15HP | |

| 2nd Top spindle | 11kw/15HP | |

| 2nd Bottom spindle | 11kw/15HP | |

| Top spindle lifting | 0.55kw/0.5HP | |

| Feeding beam lifting | 0.75kw/1HP | |

| Feeding motor | 7.5kw/10HP | |

| Total power | 71.3kw/97HP | |

| Spindle diameter(mm) | 1st Bottom spindle | φ125 |

| Right vertical spindle | φ125~φ200 | |

| Left vertical spindle | φ125~φ200 | |

| 1st Top spindle | φ125~φ200 | |

| 2nd Top spindle | φ125~φ200 | |

| 2nd Bottom spindle | φ125~φ200 | |

| Remar | Feeding wheel diamter(mm) | φ140 |

| Dust outlet diameter(mm) | φ140 | |

| Overall dimensions(mm) | L5000*W2000*H1950 | |

| Weight(kg) | 4500 | |

| Air volume | 12800m³/h |

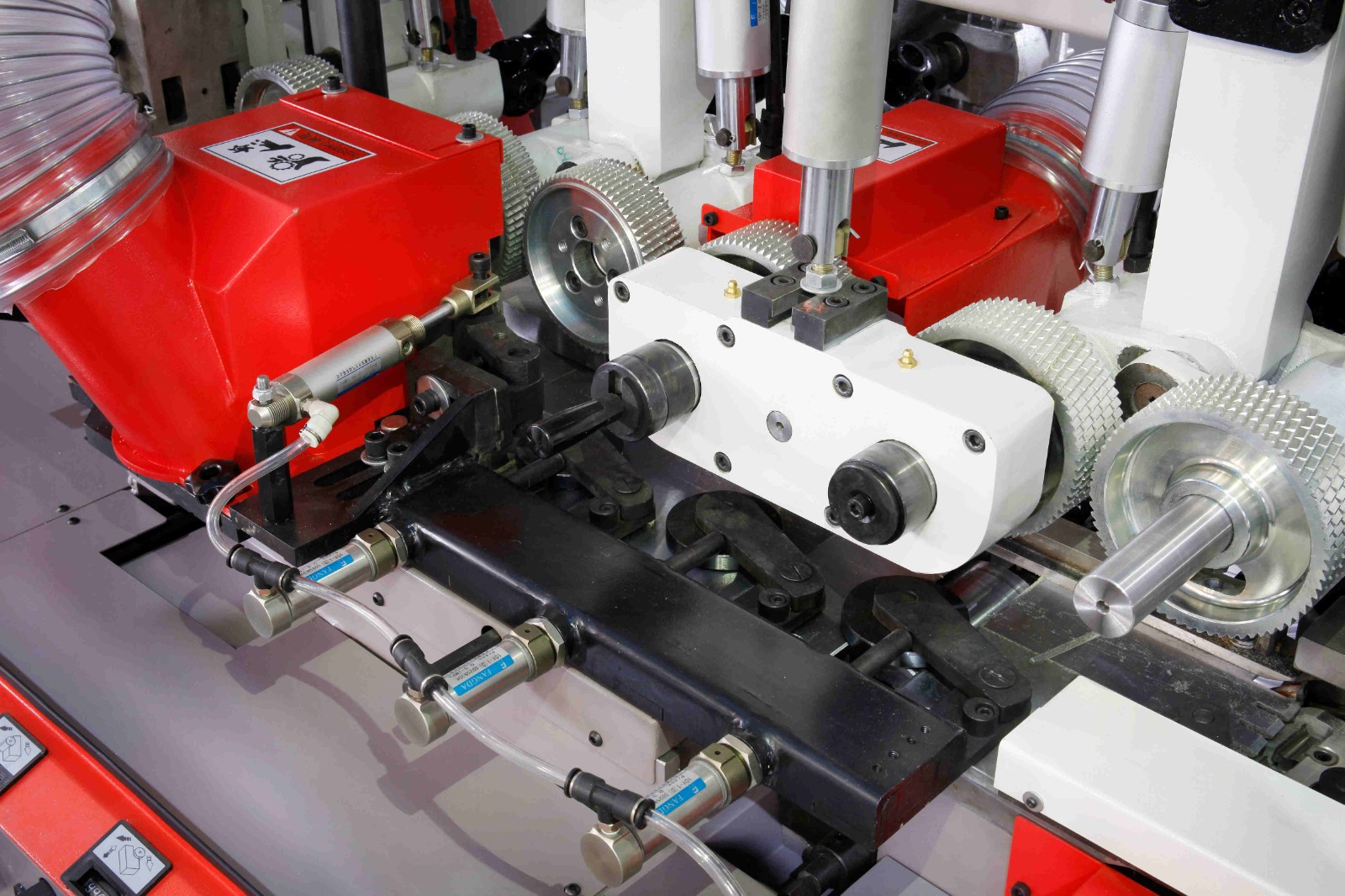

Machine structure

Precisely ordered internal structure.

(12 groups of feeding rollers, 6 groups of lower rollers, smooth and powerful feeding)

Pneumatic compression system.

(left vertical shaft side guide wheel set is equipped with cylinder, side pressing wood is stable)

The upper shaft is equipped with two sets of feeding systems.

(feed smoothly and forcefully with large cutting volume

The front pressure plate is equipped with pneumatic compression.

(the pressing plate before the knife adopts double cylinder pressing device, so the pressing material is more stable.)

Copyright © 2020 V-hold Woodworking Machinery Manufacturing Co., Ltd. | All Rights Reserved Sitemap