Working width: 25-210mm

working thickness: 8-150mm

working table length: 1970mm

feeding speed: 6-36m/min

Main shaft diameter: 40mm

Main shaft revolution: 6000r/min

Air pressure: 0.6MPa

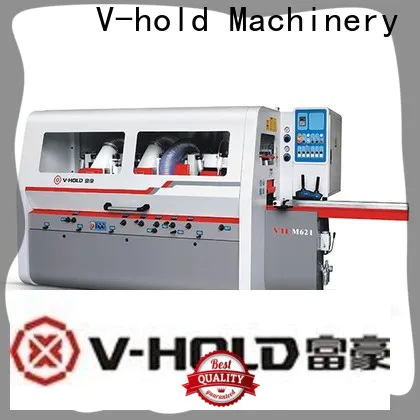

Company Advantages1. V-hold Machinery wood molder for sale is designed by talented architects or interior designers. They work hard on sorting through all the decoration options, deciding on how to blend colors, selecting materials that cater to the market trend. V-hold Machinery is a leading woodworking machinery manufacturer & supplier since 1996, main products include 4-sided moulder &

multiple rip saw2. With no filament, this product is more robust and lasts longer. This will result in saving money for users on replacement and maintenance. V-hold Machinery has over 27 years of professional four-sided plane production & wood board production

3. The highest international quality standards are applied in its production.

4. After our strict quality control, all defects of the product have been thoroughly removed.

5. The quality of the product is fully assured as we have been sticking to 'quality first' since the establishments.

Heavy Duty

VH-M621/521

Professional solution for processing Medium cutting capacity strip,

MDF strip, HDF strip, floor, doors, Solid wood furniture and Square

boards.

| Model |

| VH-M621 | VH-M521 |

| Specification | Working width | 25-210 | 25-210 |

| Working thickness | 8-140 | 8-140 |

| Working table length | 1970 | 1700 |

| Feeding speed | 6-36 | 6-36 |

| Mian spindle diameter (mm) | Φ 40 | Φ 40 |

| Main spindle revolution(r/min) | 6500 | 6500 |

| Air pressure (Mpa) | 0.6 | 0.6 |

| Motor power(KW) | 1st LowerShaft | 5.5kw/7.5HP | 5.5kw/7.5HP |

| Right vertical spindle | 5.5kw/7.5HP | 5.5kw/7.5HP |

| Left vertical spindle | 5.5kw/7.5HP | 5.5kw/7.5HP |

| 1st UpperShaft | 5.5kw/7.5HP | 5.5kw/7.5HP |

| 2nd UpperShaft | 5.5kw/7.5HP |

|

| 2nd Lower Shaft | 5.5kw/7.5HP | 5.5kw/7.5HP |

| Feeding beam lifting | 0.55kw/0.75HP | 0.55kw/0.75HP |

| Feedingmotor | 4kw/5.5HP | 4kw/5.5HP |

| Total power | 39.55kw/54.3HP | 34.05kw/46.26HP |

| Cutter diameter | 1st Lower Shaft | Φ 125 | Φ 125 |

| Right Vertical spindle | Φ 125-Φ 180 | Φ 125-Φ 180 |

| Left vertical spindle | Φ 125-Φ 180 | Φ 125-Φ 180 |

| 1st Upper Shaft | Φ 125-Φ 180 | Φ 125-Φ 180 |

| 2nd Upper Shaft | Φ 125-Φ 180 |

|

| 2nd Lower Shaft | Φ 125-Φ 200 | Φ 125-Φ 200 |

| Remark | Feeding wheel diameter (mm) | Φ140 | Φ140 |

| Dust outlet diameter(mm) | Φ140 | Φ140 |

Heavy cutting gear box Nourishment wheel via a universal joint and the gearbox, ensure no power loss. Feeding extremely smooth, powerful driving force, high feedind accuracy.

Every spindle is tested and assembled in dust free room, with SKF bearing on the double end before finished. Absolute smooth running of the spindle ensure the finished surface without any roughness.

Rapidly flip-short feeding device This mechanism effectively enhance the smooth feeding of short material, auxiliary feed wheel has a drive power to make feeding more brisk. Feeding off the wheel, easy to replace the tool and calibrated.

Moveable working table on the last bottom spindle, Making easy working on changing cutters.

Exquisite production technology, internal precision machinery.

Company Features1. Our company is fortunate to embrace many professional operations managers. They quite understand our company's overall mission and goals, and use their ability to think analytically, communicate effectively, and execute efficiently to ensure efficient operations.

2. Pursuit of excellence is the consistent commitment of V-hold Machinery. Call!