Company Advantages1. Removal of the edge, or flash, from a V-hold Machinery wood planer for sale can be accomplished in a number of ways including manual tear trimming, cryogenic processing, tumbling precision grinding. V-hold Machinery has over 27 years of professional four-sided plane production & wood board production

2. Except reliable quality assurance, high-quality after-sales service is also important in V-hold Machinery.

3. The product is strong because designing and manufacturing are executed using highly automated machines and computer-aided designing technology, which effectively result in products with great structural strength. V-hold Machinery is a leading woodworking machinery manufacturer & supplier since 1996, main products include 4-sided moulder &

multiple rip saw4. The product is highly resistant to wear. This product is coated or painted with the abrasion-resistant finish which can protect its surface.

5. It is effective for people who have allergies because they repel dust mites and also provide a cool and soft sleeping surface that is free of allergens.

VH-MB2045D

| SPECIFICATION AND MODEL | MB2045D |

| Max. working width (mm) | 450 |

| Max. working thickness (mm) | 150 |

| Min. working thickness (mm) | 15 |

| Min. working length (mm) | 320 |

| Cutter knife | 4 |

| Flat knife spec | 450*30*6 |

| Spindle rotation rate | 4500 |

| Feeding speed | 5~16 |

| Spindle dia | Φ 110 |

| Top spindle power | 7.5 |

| Bottom spindle power | 5.5 |

| Feeding motor power | 2.2 |

| Elevating motor power | 0.37 |

| Total power | 15.57 |

| Dimension | 2280*1260*1680 |

| SPECIFICATION AND MODEL | MB2063 | MB2045D | MB2040 | MB2032 |

| Max. working width (mm) | 635 | 450 | 405 | 320 |

| Max. working thickness (mm) | 200 | 150 | 170 | 120 |

| Min. working thickness (mm) | 15 | 15 | 15 | 15 |

| Min. working length (mm) | 320 | 320 | 320 | 320 |

| Cutter knife | 4 | 4 | 4 | 4 |

| Flat knife spec | 635*30*6 | 450*30*6 | 405*30*6 | 320*30*6 |

| Spindle rotation rate | 5000 | 4500 | 5000 | 5000 |

| Feeding speed | 5~20 | 5~16 | 5~16 | 5~16 |

| Spindle dia | Φ 110 | Φ 110 | Φ 110 | Φ 110 |

| Top spindle power | 11 | 7.5 | 7.5 | 5.5 |

| Bottom spindle power | 7.5 | 5.5 | 5.5 | 4 |

| Feeding motor power | 2.2 | 2.2 | 1.5 | 1.5 |

| Elevating motor power | 0.37 | 0.37 | 0.37 | 0.37 |

| Total power | 21.07 | 15.57 | 14.87 | 11.37 |

| Dimension | 2700*1268*1680 | 2280*1260*1680 | 2220*950*1650 | 1880*780*1650 |

VH-MB2045D

Working width 450mm

Attached flat knife shaft

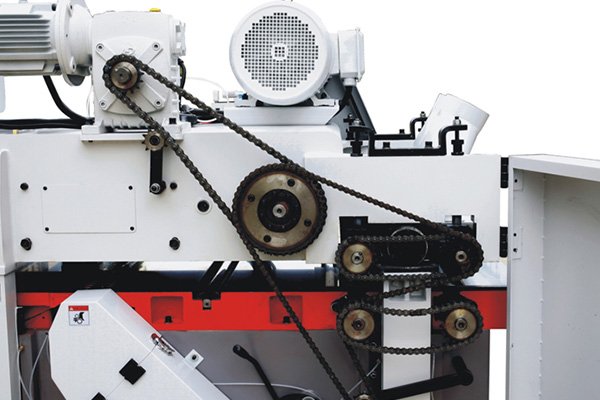

Feeding Frequency

After driving roller workbench configuration

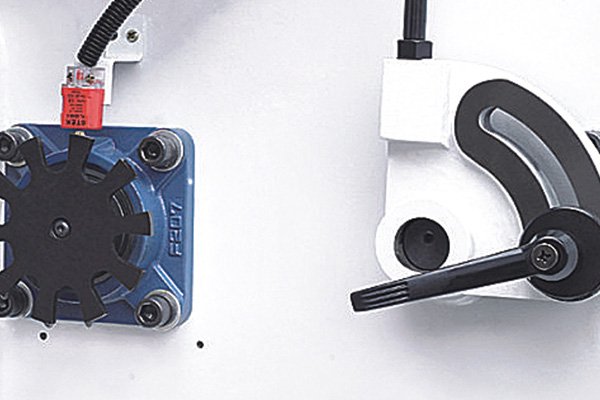

Centralized lubrication system

Centralized lubrication systemThe configuration set to the cent ralized lubrication system, facilitate the lifting system maintenance lubrication.

Feeding frequency inverter

Feeding frequency inverterDigital display, easy operation, energy saving,reduction of mechanical transmission wear.

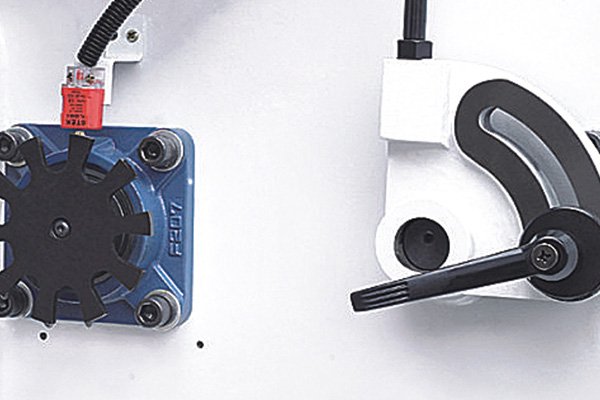

Thickness Quick set

Thickness Quick setSimply preset thickness timber placed at the microswitch, you can do simple thickness settings.

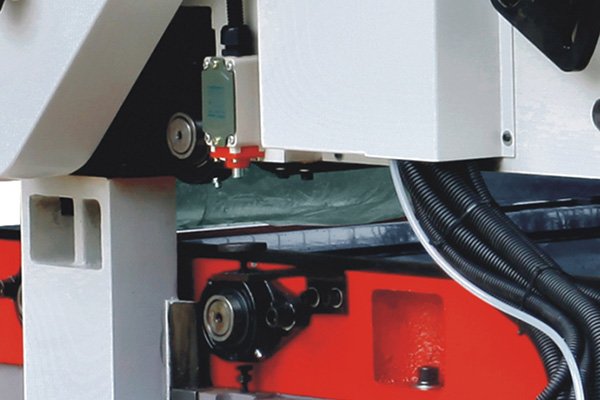

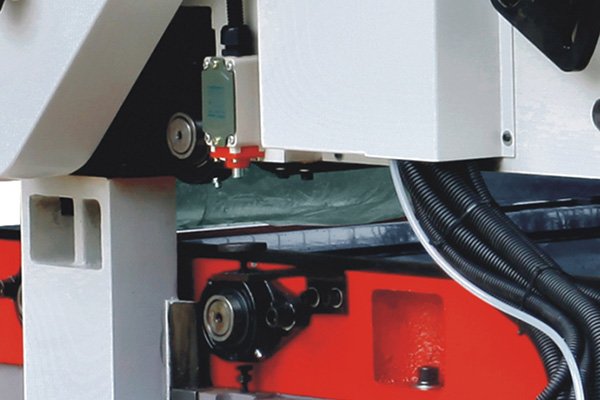

Gate magnetic induction switch

Gate magnetic induction switchThe thickness of the display gate magnetic sensors,accuracy is much higher than conventional proximity sensor.

Rear operation box

Rear operation boxMachine emergency stop or abnormal reactions only feed stop and start.

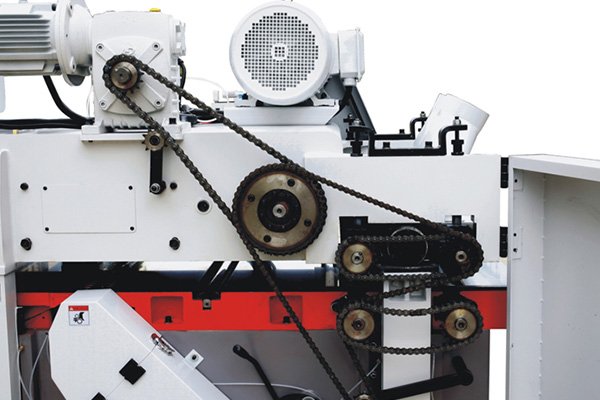

Feeding device is with clutch, which can prevent overload and give a safe operation.

Auto grease device keeps the machine always lubricated during working.

Alarm detector: When overload or stripping occurs with feeding chain, the alarm switch will give out signal alarm.

The product is provided with imported digital display device,which can be operated directly to processing thickness from operating panel with the accuracy up to 0.05mm; besides,upper and lower planning motor is provided with current meter for visual observing if it is overloaded while working.

3. Standard Configuration Option

Flat knife blade

MB2045D:Blade size(450X30X6MM)X8PCS

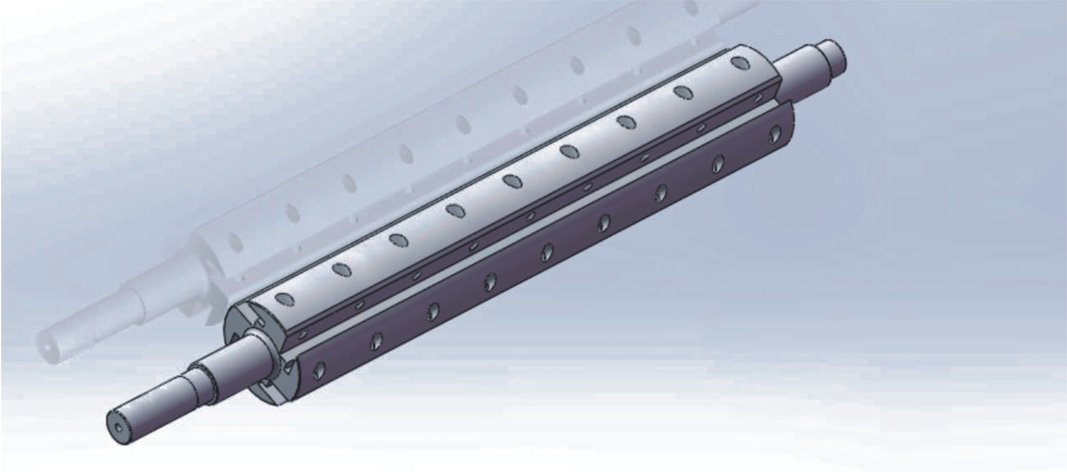

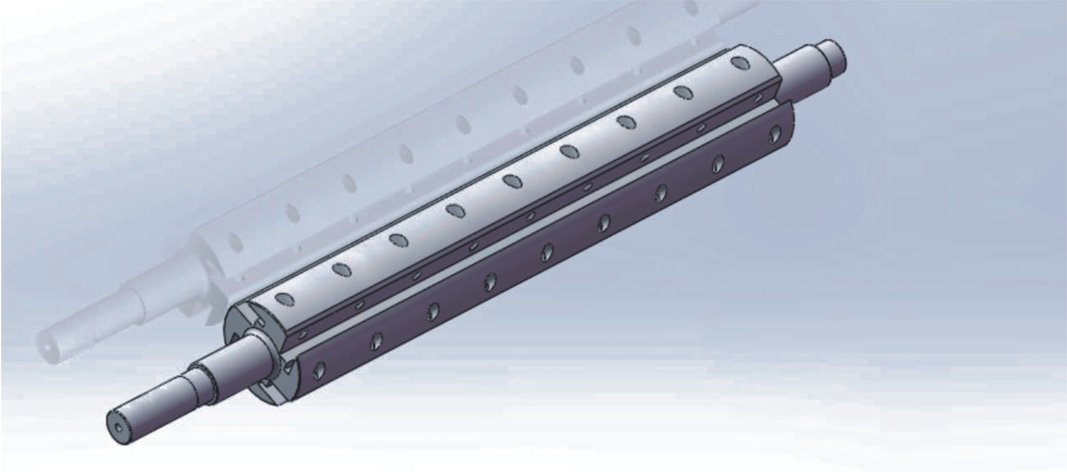

Screw arbor (Heavy Duty)

Arbor screw precision machining

Provide fine planing surfacing, and no noise

Arbor screw assembly removable tungsten carbide blade

MB2045:Blade size (30×12×1.5)×63pcs

Company Features1. We have good supervision of production for double sided wood planer .

2. Our business philosophy is to pro-actively corporate with our suppliers that comply with ethical practices and help our customers find innovative and timely solutions.