Related Products

V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

Aggregated Oversize

VH-M633V

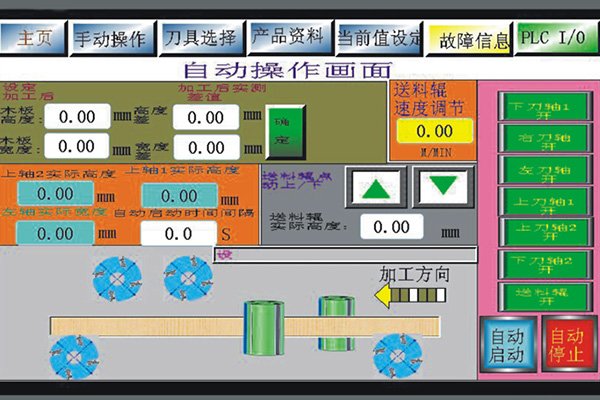

| Model | VH-M623V | |

| Specification | Working width(mm) | 50-230 |

| Working thickness (mm) | 8-160 | |

| Working table length (mm) | 1970 | |

| Feeding speed (mm) | 6-36 | |

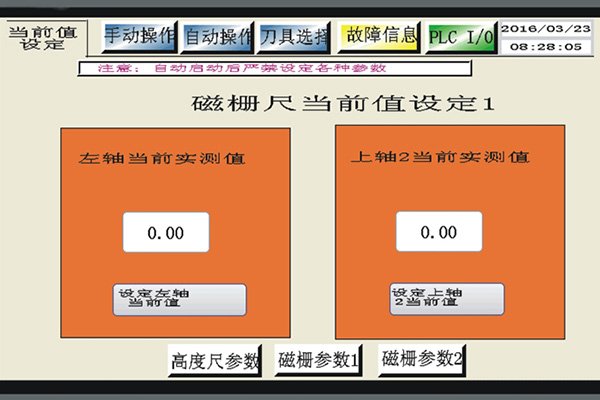

| Mian spindle diameter (mm) | Φ 40 | |

| Main spindle revolution (r/min) | 6500 | |

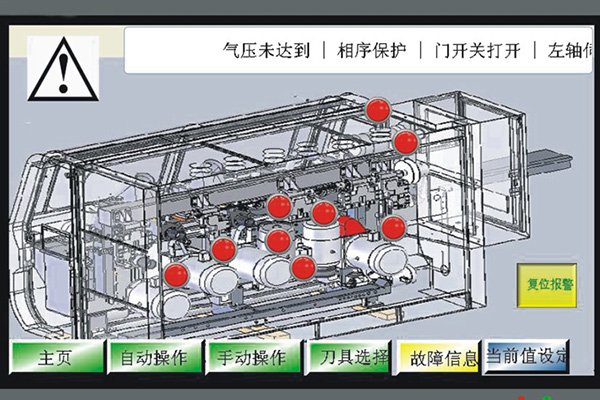

| Air pressure (Mpa) | 0.6 | |

| Motor power (KW) | 1st Lower Shsft | 11kw/15HP |

| Right vertical spindle | 11kw/15HP | |

| Left vertical spindle | 11kw/15HP | |

| 1st Upper Shaft | 15kw/20HP | |

| 2nd Upper Shaft | 15kw/20HP | |

| 2nd Lower Shaft | 11kw/15HP | |

| Top spindle lifting | 0.55kw/0.75HP | |

| Feeding beam lifting | 0.75kw/1HP | |

| Feeding motor | 7.5kw/10HP | |

| Left vertical adjustment | 0.18kw/0.25HP | |

| Total power | 82.98kw/112.74HP | |

| Cutter diameter | 1st Lower Shsft | Φ 125-Φ 140 |

| Right Vertical spindle | Φ 125-Φ 200 | |

| Left vertical spindle | Φ 125-Φ 200 | |

| 1st Upper Shaft | Φ 125-Φ 200 | |

| 2nd Upper Shaft | Φ 125-Φ 200 | |

| 2nd Lower Shaft | Φ 125-Φ 200 | |

| Remark | Feeding wheel diameter | Φ140 |

| Dust outlet diameter | Φ140 |

Copyright © 2020 V-hold Woodworking Machinery Manufacturing Co., Ltd. | All Rights Reserved Sitemap