V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

V-hold Machinery - Woodworking Machinery Manufacturer Focusing on Solid Wood Machinery that to be the excellence brand !

| VH-ML9321 Multiple rip saw with Double side planer FUNDATION:The front part is the top and bottom horizontal spindle, and multiple rip saw in the behind, which is a woodworking machine combining the functions of double-sided planer and multi-saw. The feeding system is use heavy duty reducer to drive the universal joint drive roller. If the width of the wood exceeds the maximum working width of the model, we can open the lid to process the wood more easily and flexibly. The power of VH-ML9321 is 22kW, which can process wood with thickness 70 mm and width 210 mm. For boxboard,shutter,wood joist/wood keel. |

Technical data

SPECIFICATION AND MODEL | VH-ML9321 |

| Max. working width(mm) | 210mm |

| Max. working thickness(mm) | 70mm |

| Feeding speed(m/min) | 4-18m/min |

| Top spindle diameter(mm) | 40mm |

| Top spindle rotation rate(r/min) | 6000r/min |

| Top spindle movement(mm) | 20mm |

| Top spindle motor power(kw) | 5.5kw |

| Bottom spindle diameter(mm) | 40mm |

| Bottom spindle rotation rate(m/min) | 6000r/min |

| Bottom spindle motor power(kw) | 4kw |

| Cutting spindle diameter(mm) | 50mm |

| Cutting spindle rotation rate(m/min) | 4000r/min |

| Max. saw blade diameter(mm) | 300mm |

| Spindle power(kw) | 22kw |

| Spindle elevating motor(kw) | 0.37kw |

| Feeding motor power(kw) | 2.2kw |

| Elevating motor power(kw) | 0.37kw |

| Total power(kw) | 34.44kw |

| Air pressure(Mpa) | 0.6Mpa |

| Dimension(mm) | 3070×1230×1540mm |

Excellent properties for VH-ML9321

|  |  |  |

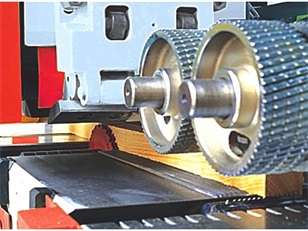

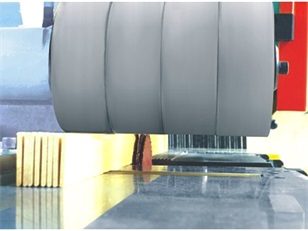

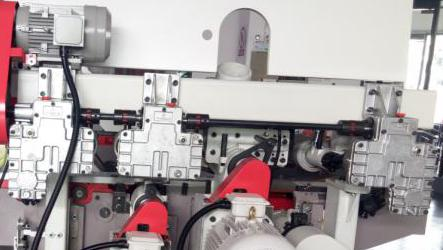

The foregoing press-plates can process short materials. | Working table and rear pressure panel use U shape guiding groove structure, ensure the arcsymmetry of the multiple leaves. | Anti-return system, gureented the operator to be not damaged by returned wood chips. | Exquisite production technology with orderly inside. |

|  |  |  |

Semi-open cover The outer cover of the equipment is in the form of semi-open, which can make the wood exceeding the processing width pass smoothly, flexible and convenient | Simple operation interface The operation panel adopts Siemens upper second house APT button, and all operations are completed on the panel, equipped with fault indicator, emergency stop, electric lift button and so on. | Heavy-cut gearbox The feeding wheel is driven by universal joint and gearbox to ensure no power loss and strong feeding. | Electric lifting of saw shaft The button type is used to control the rise and fall of the saw blade spindle, which is convenient and fast, and improves the operation efficiency. |

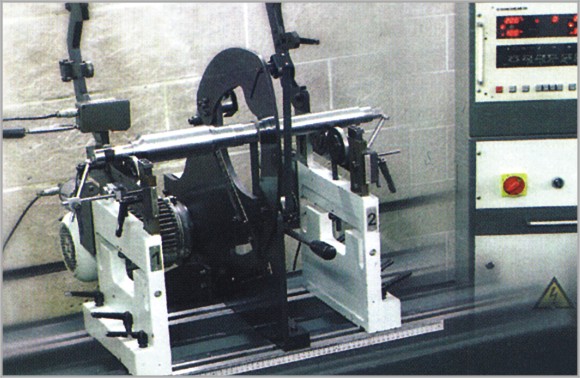

Product show

PROCESSING TECHNIC

|  |  |  |

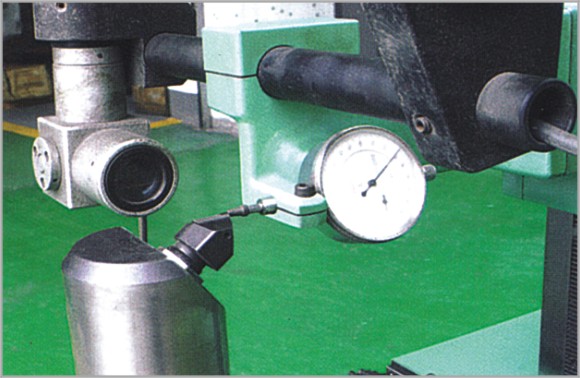

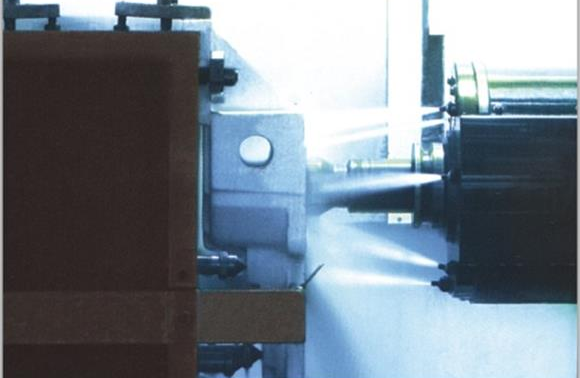

Rigid body structure of bed Cast cast iron with shock absorption performance to ensure smooth operation of tool shaft and feeding system. | Excellent processing equipment Meticulous careful production to ensure that each part is almost perfect! | Japan Four-axis Joint Machining Centre All shaft frame, reducer and other accessories, the company is equipped with its own processing center to ensure the precision of accessories. | Spindle Dynamic Balance Testing Each spindle carries out dynamic balance testing, equipped with imported SKF bearings to ensure high precision and smooth operation of the cutter shaft. |

Accreditation: QUALIFICATION

Copyright © 2020 V-hold Woodworking Machinery Manufacturing Co., Ltd. | All Rights Reserved Sitemap