Working width: 50-230mm

working thickness: 8-160mm

working table length: 1970mm

feeding speed: 6-36m/min

Main shaft diameter: Φ 40

Main shaft revolution: 6500r/min

Air pressure: 0.6MPa

Company Advantages1. The tests on V-hold Machinery molding wood machine such as robustness testing and water resistance testing conducted by our quality department start with raw material acceptance and continue strictly at every step of each production process. V-hold Machinery is a leading woodworking machinery manufacturer & supplier since 1996, main products include 4-sided moulder &

multiple rip saw2. This product has long been the favorites of many households and business owners. It incorporates practical and elegant elements to fit the space.

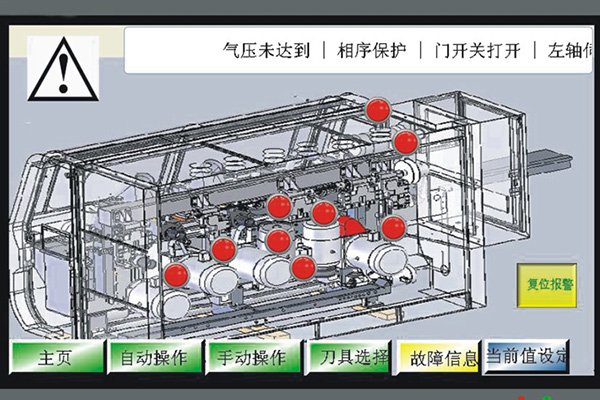

3. The product features satisfactory electromagnetic compatibility. It is able to function stably in its electromagnetic environment without introducing intolerable electromagnetic disturbance to anything. V-hold Machinery has over 27 years of professional four-sided plane production & wood board production

4. This product is safe to use. With its built-in protective systems, including overload and overvoltage protective devices, it generates no danger.

5. It is highly chemical resistant. Its surface is treated with a protective chemical coating or with protective paintwork to prevent chemicals.

Aggregated Oversize

VH-M633V

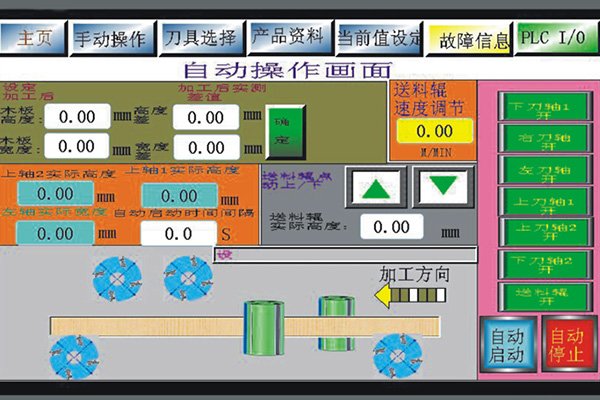

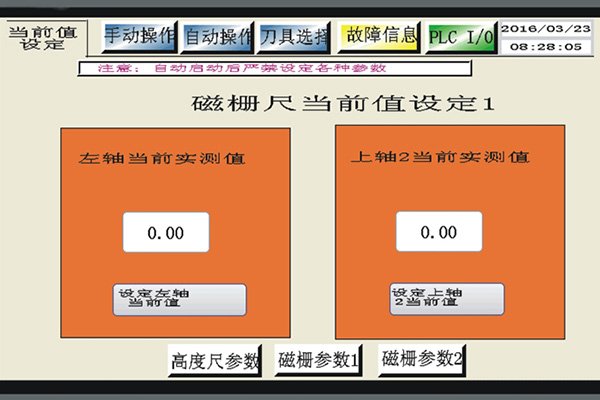

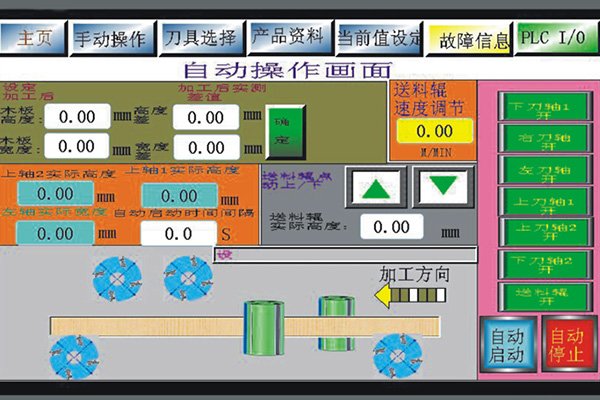

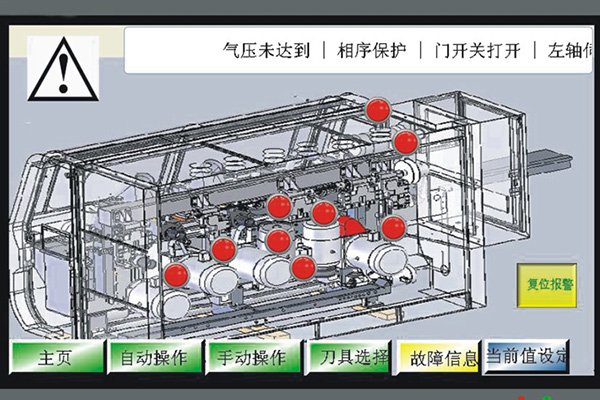

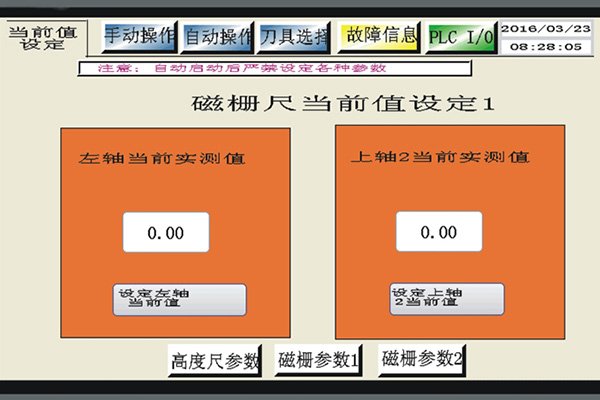

interface control

All parameters can be set in the

mechanical interface. Product

information, tool date, width and

thickness can be set in the man-

machine interface, and displayed

in the interface. Feed speed, each

spindle interval can be written in

the interface

High quality touch control system

One-button solution>

High-quality machining results

High-quality machining results

Boost efficiency and shorten time to adjust

Powerful features

| Model |

| VH-M623V |

| Specification | Working width(mm) | 50-230 |

| Working thickness (mm) | 8-160 |

| Working table length (mm) | 1970 |

| Feeding speed (mm) | 6-36 |

| Mian spindle diameter (mm) | Φ 40 |

| Main spindle revolution (r/min) | 6500 |

| Air pressure (Mpa) | 0.6 |

| Motor power (KW) | 1st Lower Shsft | 11kw/15HP |

| Right vertical spindle | 11kw/15HP |

| Left vertical spindle | 11kw/15HP |

| 1st Upper Shaft | 15kw/20HP |

| 2nd Upper Shaft | 15kw/20HP |

| 2nd Lower Shaft | 11kw/15HP |

| Top spindle lifting | 0.55kw/0.75HP |

| Feeding beam lifting | 0.75kw/1HP |

| Feeding motor | 7.5kw/10HP |

| Left vertical adjustment | 0.18kw/0.25HP |

| Total power | 82.98kw/112.74HP |

| Cutter diameter | 1st Lower Shsft | Φ 125-Φ 140 |

| Right Vertical spindle | Φ 125-Φ 200 |

| Left vertical spindle | Φ 125-Φ 200 |

| 1st Upper Shaft | Φ 125-Φ 200 |

| 2nd Upper Shaft | Φ 125-Φ 200 |

| 2nd Lower Shaft | Φ 125-Φ 200 |

| Remark | Feeding wheel diameter | Φ140 |

| Dust outlet diameter | Φ140 |

Each movement of universal spindle is controlled by electric reduce the laboring.

Auto picture, easy to operate, a key to solving

Intelligent automatic self-detection systems, monitoring equipment to run at any time

Tool Database

Any position can be set as the origin

Company Features1. All our technical staff are rich in experience for four side moulder woodworking machine .

2. Our company bears social responsibility. We continuously assess our production methods and resource use to improve our energy efficiency and lower our environmental footprint.