How did V-hold Woodworking Machine design double end tenoner ?

2023-05-27

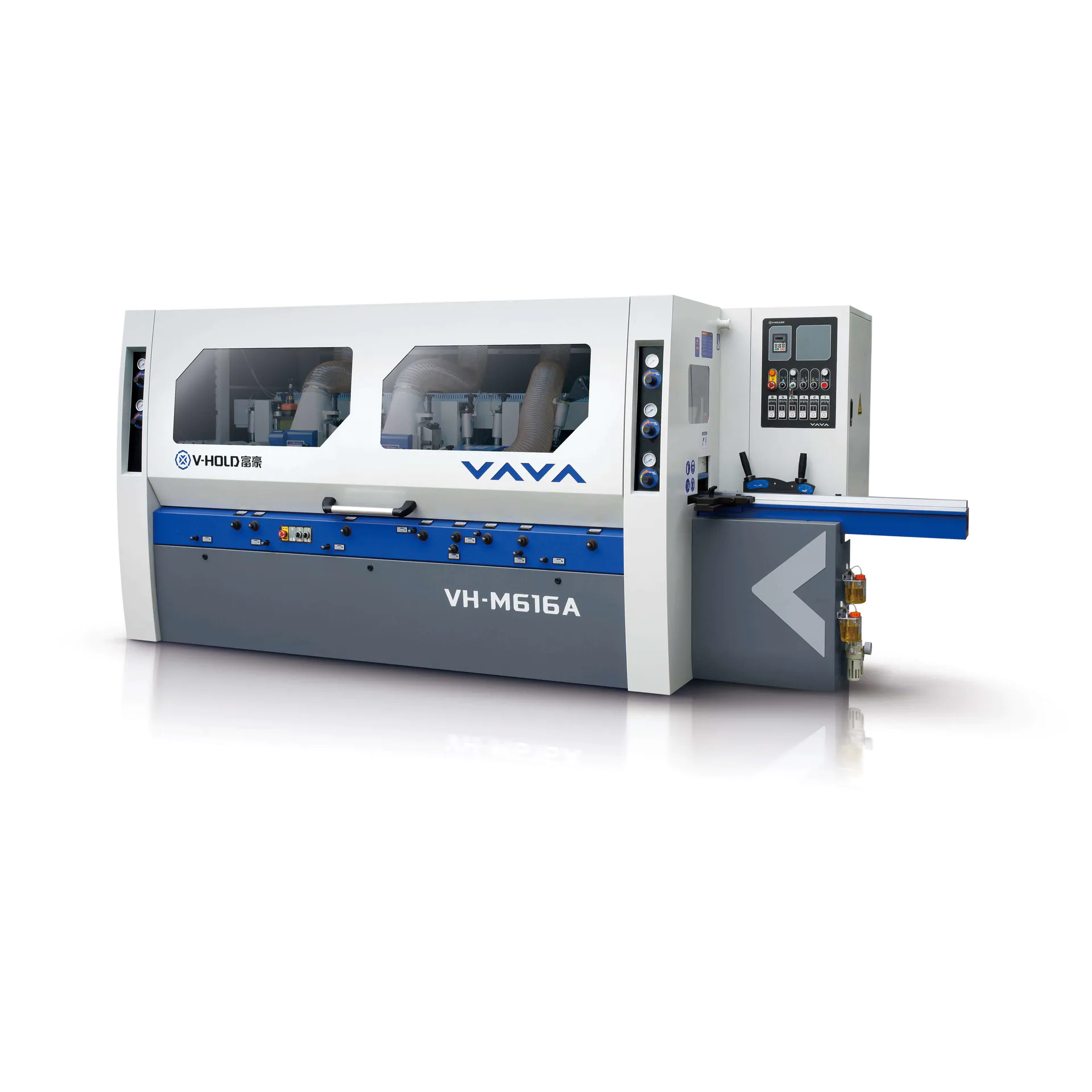

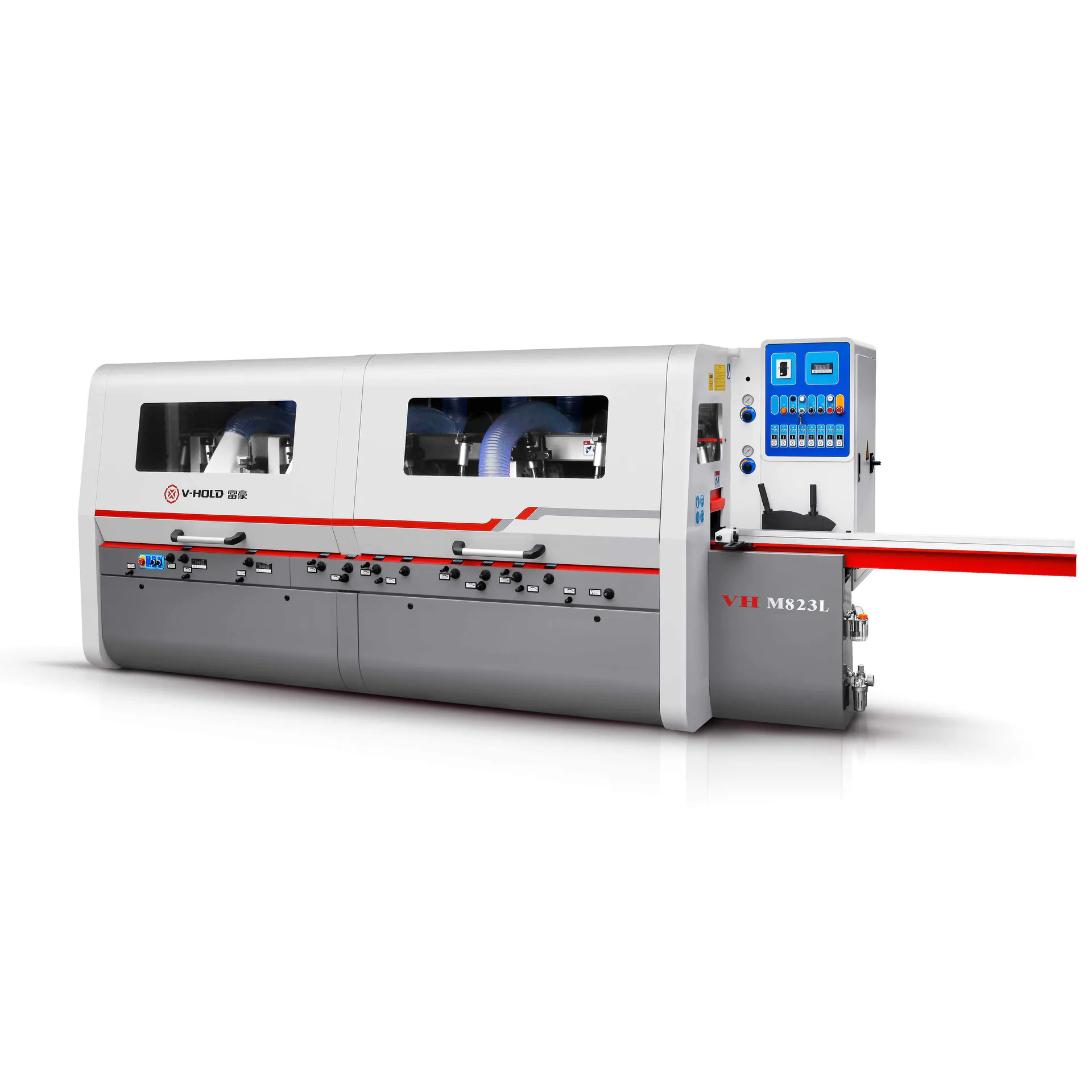

The design process of double end tenoner can be finished through 4 steps. Concept developing and product design planning come first. Our designers and technicians work together for the expected product performance and appearance design. The detailed design process comes next. Based on the results of the discussion, our designers should consider the materials processing, target application fields, and user experience comprehensively when conducting the product design rather than focusing on the product shapes, colors, and specifications only. Then, designers will deliver the product drawings or sketches to every department of our company for feedback collecting. The last step is the final confirmation. After reaching a mutual agreement on the product design between customers and us, the product design process is finished and the sample will be made based on the design sketches.

As a reliable manufacturer, v-hold woodworking machinery manufacturing co;lto occupies an important position in the global wood molder for sale market. V-hold Woodworking Machinery Manufacturing Co., Ltd focuses on providing a variety of double end tenoner for customers. The stable performance and long lifespan make the product stand out from competitors. V-hold Machinery is a leading woodworking machinery manufacturer & supplier since 1996, main products include 4-sided moulder & multiple rip saw. People can expect this garment to be sturdy enough that they can move without having to worry about ripping seams. V-hold Machinery has over 27 years of professional four-sided plane production & wood board production.

We always adhere to the customer-oriented concept. We will offer customer-oriented services and spare no efforts to offer customers quality products that are professionally manufactured.

As a reliable manufacturer, v-hold woodworking machinery manufacturing co;lto occupies an important position in the global wood molder for sale market. V-hold Woodworking Machinery Manufacturing Co., Ltd focuses on providing a variety of double end tenoner for customers. The stable performance and long lifespan make the product stand out from competitors. V-hold Machinery is a leading woodworking machinery manufacturer & supplier since 1996, main products include 4-sided moulder & multiple rip saw. People can expect this garment to be sturdy enough that they can move without having to worry about ripping seams. V-hold Machinery has over 27 years of professional four-sided plane production & wood board production.

We always adhere to the customer-oriented concept. We will offer customer-oriented services and spare no efforts to offer customers quality products that are professionally manufactured.

Custom message